Typically, when engine mounts (engine mounting insulators) deteriorate, uncomfortable vibrations occur during idling, or loud “thud” sounds are heard during initial acceleration, making it impossible to leave them unattended.

Toyota’s first-generation Vitz, which never had its engine mounts replaced and never exhibited such discomfort, has approached a mileage of 320,000 kilometers.

2003 model UA-SCP10 1SZ-FE 5MT Mileage 318,000km

The large, heavy mass formed by the engine and transmission is supported by three engine mounts within the engine compartment.

The right and left mounts are positioned at the top, with the image of suspending the heavy object.

On the other hand, the rear mount is located much lower than the other two mounts and is placed on the suspension cross member. The main role of the rear mount is to prevent rotational movement of the engine and transmission rather than supporting weight.

During last year’s engine replacement, as a used engine came with the right-side mount, I used that for the right side, but I chose to continue using the left and rear mounts as they showed no noticeable deterioration and there were no perceptible issues.

Then, after driving about 20,000 kilometers since the engine replacement, there was a complaint about a faint “knock” sound coming from the front left during initial acceleration. I inspected the suspension and exhaust pipe joints, but found no abnormalities.

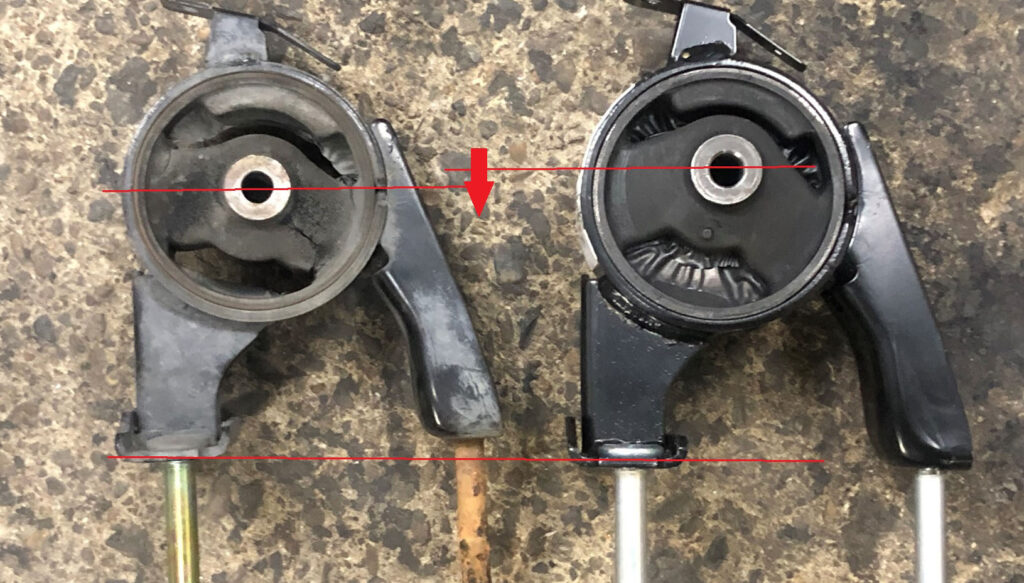

Although I thought it unlikely, when I removed the left-side mount, I found that the mounting rubber had completely torn and was in a loose state.

As mentioned earlier, there are usually perceptible issues before deterioration progresses this far, but in this particular model, there was only a faint noise. As expected from Toyota (?)

I also checked the rear mount.

The center of the mount had sagged, but there were no major cracks, just fine hairline cracks.

The two long studs are likely for ease of assembly during manufacturing. When manufacturing processes are prioritized, consideration for aftermarket service situations (like replacing just the engine mount in this case) is often lacking (especially in imported vehicles). However, the fact that these seemingly difficult-to-remove studs with their long length can be easily removed and installed if the correct procedure is followed, makes me think this is a small act of thoughtfulness from the designers.

Since the left-side mount was completely torn, after replacing it with a new one, the excess movement of the heavy engine and transmission was eliminated, making shifting and clutch operation significantly smoother.

As is characteristic of manual transmissions, drivers adjust their accelerator and clutch operation to accommodate engine mount issues, so the owner seems to have only felt a slight discomfort.

If you start to feel that your clutch operation is becoming awkward, the cause might be deteriorated engine mounts.

TOYOTA Genuine Parts Vitz 【NCP131 KSP130 NSP130/135】 Rear Charm 【Onyx】 08231-52390

Leave a Reply