I’ll translate the HTML content from Japanese to English while preserving the HTML structure as requested.

Title: Troubleshooting an Alfa Romeo Semi-Automatic Transmission Stuck in Neutral (Alfa 147 2.0TS selespeed)

The Selespeed, Alfa Romeo’s famous semi-automatic mechanism, is a hydraulic robot that operates a manual transmission in place of a human. When installed in Fiat vehicles it’s called Dualogic, and in Lancia it’s called DFN with some external differences, but the hydraulic tank has “SELESPEED” embossed on it, so you can consider them all as similar mechanisms manufactured by Magneti Marelli.

I haven’t examined many Selespeed systems, so I often reference online failure cases expecting certain patterns of malfunction, but even with a quick look, I’m amazed at the variety of problems and irregularities and how elusive they can be to diagnose.

Similar air pressure-based mechanisms are commonly found in large buses and trucks, and there’s no question about the mechanical principles, but when it comes to Selespeed, enthusiasts say that “breakdowns are normal, unexpected malfunctions are natural, and a well-functioning Alfa Romeo is beautiful precisely because it’s ephemeral.” Apparently, that’s the mindset you need to drive one.

2006 model GH-937AB Twin Spark 2.0 Selespeed, 65,000 km mileage

Since I don’t hear good things about them, I always tell owners to avoid long-distance drives, but in early March this year, I received a panicked call from a customer saying their car was stuck in neutral and couldn’t shift gears at a location far from Kyoto.

After asking more questions, I learned that it wasn’t a continuous problem—restarting the engine generally restored function, so they carefully and slowly made their way back home. Along the way, there were instances when the car got stuck in neutral and couldn’t shift, and just before reaching their destination, it couldn’t shift out of first gear, but they managed to arrive at their home garage.

It was a busy period so I couldn’t inspect it right away, but I eventually headed to their nearby garage with a laptop equipped with diagnostic tools.

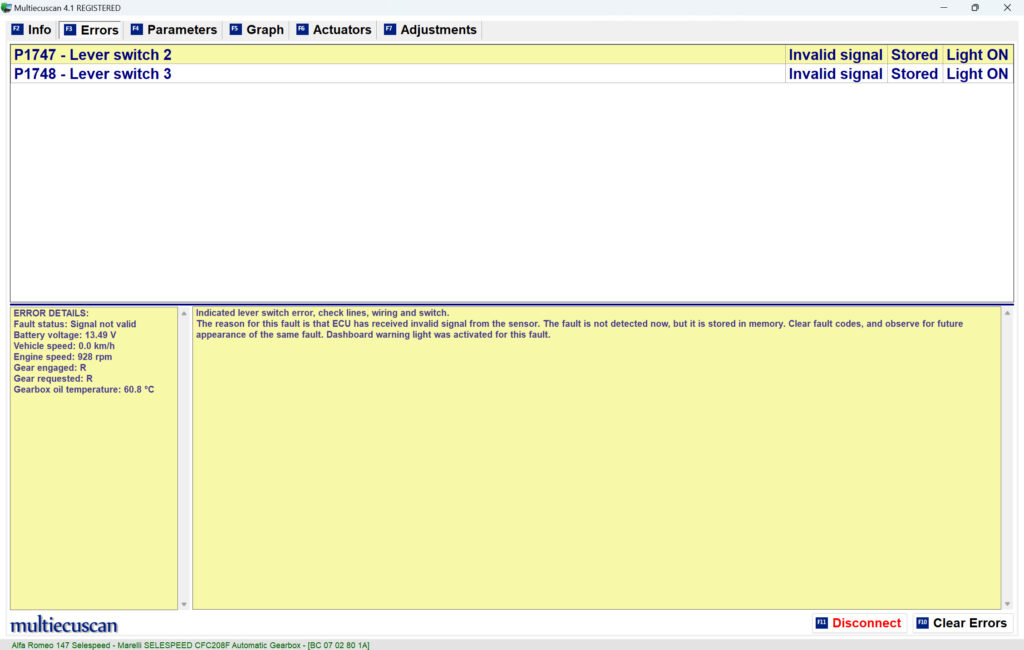

There were two lever switch failures that weren’t present during the last regular inspection. Since these aren’t ongoing failures, I saved the screenshot and cleared them temporarily.

The lever switch refers to the shift lever in the center console, but new parts aren’t available domestically, and ordering one would likely result in a response that it’s discontinued. Since it costs nearly 100,000 yen in the first place, it wouldn’t be smart to order without thorough investigation.

When I asked the customer about the problems again, they explained that not only would the car remain in neutral despite operating the lever switch after starting the engine, but also when slowing down from 4th or 5th gear, it should normally downshift automatically to 1st gear as the car decelerates, but several times it suddenly shifted from 3rd to neutral and then couldn’t shift anywhere else.

This seemed unrelated to the lever switch.

Since the malfunction only appears occasionally, I wanted to make some diagnostic progress, so I obtained an inexpensive used working lever switch to see if there would be any change after replacement, and ideally to see if the symptom could no longer be reproduced.

The base of the lever switch I obtained has Valeo (France) embossed on it, which is a strange combination for a Magneti Marelli (Italy) system.

This assembly has a square lever switch mounted on the base, but the base part is positioned outside the cabin (probably for manufacturing convenience), with heat shields and exhaust pipes passing underneath. Fortunately, the switch and base can be easily separated by loosening four Posidriv tapping screws, so it’s reasonable to replace just the switch portion.

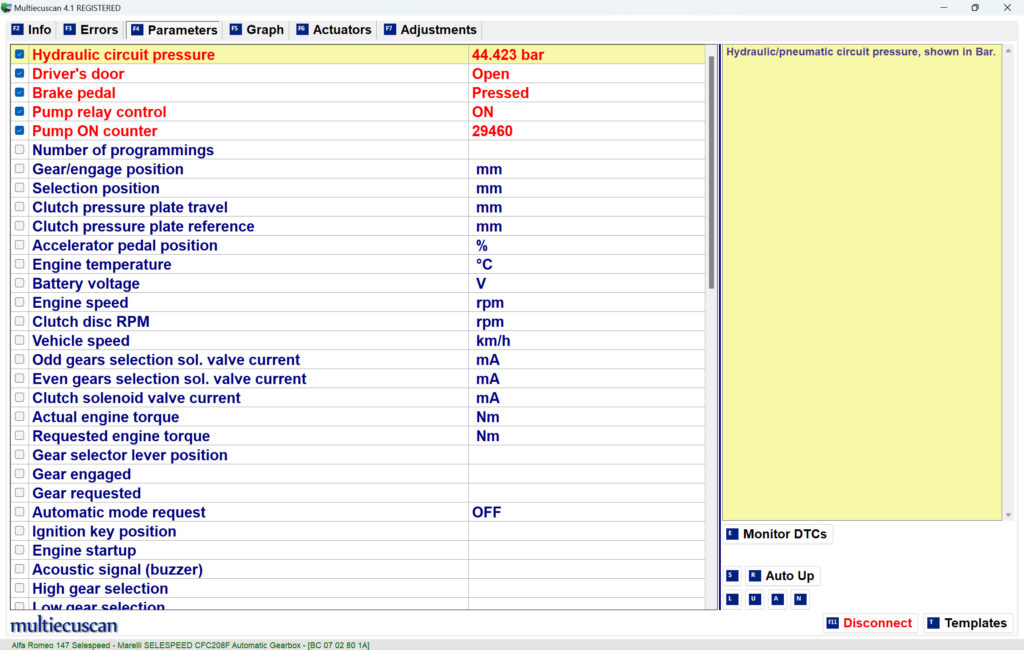

Both before and after replacing the used lever switch, I repeatedly shifted (N→1, etc.) while idling at a stop and drove around the neighborhood, but no malfunctions occurred. The hydraulic pump’s operation sound was smooth, and the system pressure on the diagnostic tool was regulated around 43-55 bar, which seemed fine. Of course, no fault codes were stored.

For a pump malfunction, it seemed to be functioning well for too long, and if it were an accumulator (pressure storage device) issue, I wouldn’t expect such stable hydraulic pressure retention. Was it really the lever switch? Something didn’t feel right.

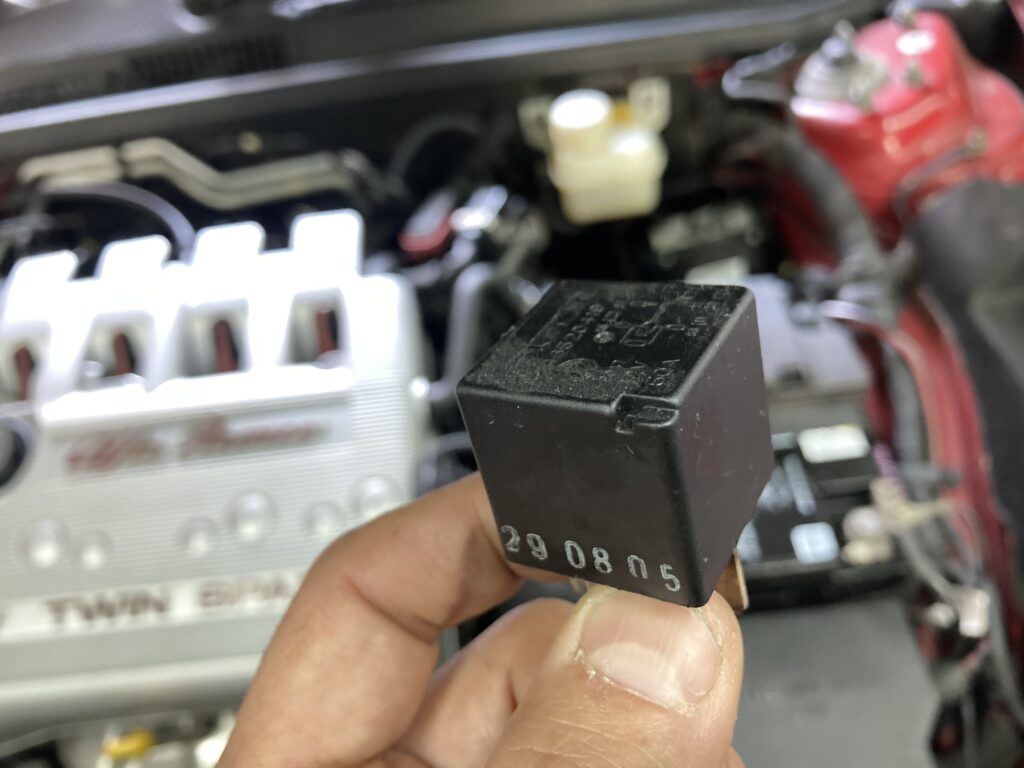

I remembered that this system has a large 50A relay that controls power to the pump.

Judging by the relay specifications, a relatively large current flows to the electromagnetic pump. Something that mustn’t be forgotten in relay circuits connected to inductive loads like electromagnetic pumps and fan motors is the large surge that occurs when power is cut off.

This relay has undergone several unexplained part number changes. I wonder if the circuit has appropriate surge absorbers or similar countermeasures? Suspecting a relay malfunction, I tried to reproduce the symptoms while idling at a stop the day after the car was brought in.

Shortly after starting the test, the car ended up in a state where it couldn’t shift out of neutral.

The system pressure fell below 43 bar where the pump should activate, and while the pump relay control was ON, the pump didn’t operate. System pressure dropped rapidly, and the failsafe kept the relay control OFF.

At this point, I replaced it with a used relay I had in stock from a 156 Selespeed.

When I turned the key ON, the system pressure rose above 50 bar with a smooth pump sound.

Testing again with the original relay, the malfunction quickly recurred. Then switching back to the 156 relay, the problem disappeared. This confirmed the relay was faulty.

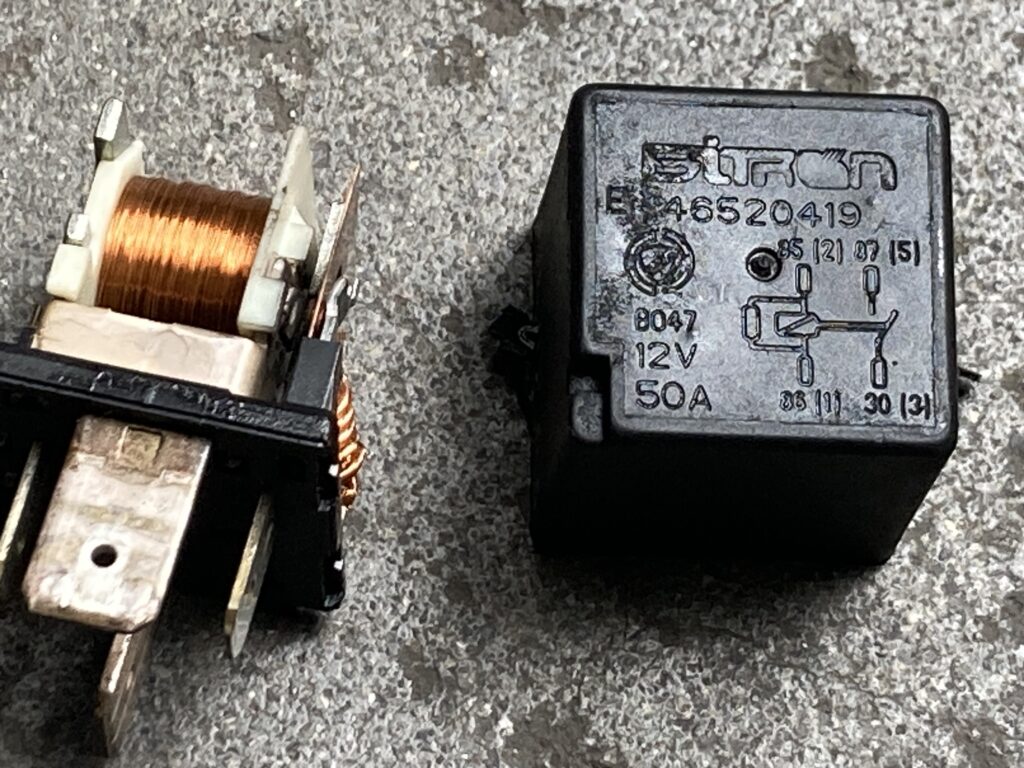

When I disassembled the original relay,

The contacts were quite deteriorated.

The genuine relay I ordered this time was not from Bitron (Italy) but from Omron Made in Italy.

Looking into it, I found that in 2004, Omron merged with and made Bitron a subsidiary to promote its automotive relay business in the European market. While the subsidiary was already established at the time this Alfa 147 was manufactured, they were still using relays with the old Bitron logo.

The diagnostic tool’s pump ON counter showed just under 30,000 cycles. Generally, a relay’s minimum lifespan is considered to be 100,000 cycles, so this was quite an early failure. I completed the repair hoping the new Omron-logo relay would have better countermeasures in place.

Despite the numerous malfunctions, the Selespeed ECU recorded no lever switch faults, nor any records of low hydraulic pressure or relay sticking as seen in other models. There’s a weak correlation between the information displayed by the diagnostic tool and the actual failures.

Leave a Reply