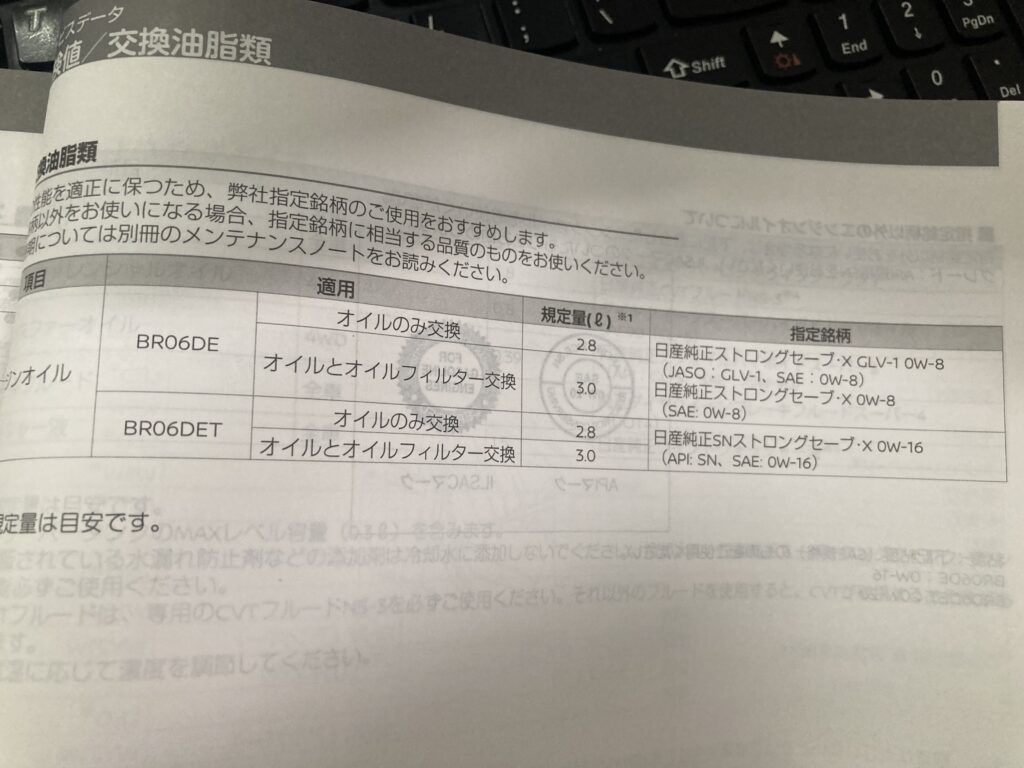

In an era where 0W-XX engine oils prioritizing fuel efficiency are becoming mainstream, we recently serviced a vehicle with the following specifications in its manual:

0W16 for turbocharged engines and 0W8 for naturally aspirated engines! The manual recommends using specified brands to maintain optimal performance.

A footnote mentioned that 0W20 could be used if the specified brand wasn’t available.

Until recently, 5W30 was acceptable, with low-viscosity oils recommended for fuel efficiency. However, for this model (likely a future trend), the manufacturer no longer approves oils with viscosities of 5W30 or higher.

As engine oil viscosity decreases, the oil film thins, simply leading to increased metal wear.

While ultra-low viscosity oils may incorporate wear-reducing technologies, fuel efficiency and wear resistance are inherently conflicting properties. Balancing both is extremely challenging.

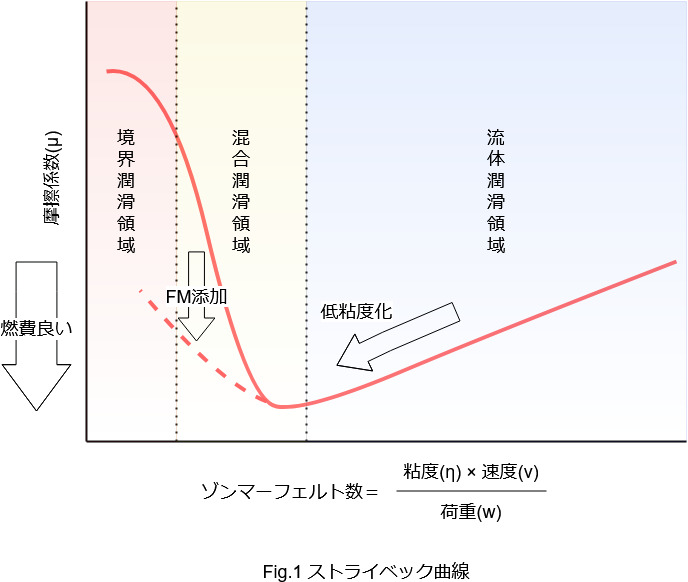

I previously introduced the Stribeck curve (Fig.1), which explains the lubrication state between two surfaces in relative motion, such as those inside an engine.

Let me explain it again:

The horizontal axis represents the Sommerfeld number, which is a function of lubricant viscosity (η), relative velocity of the two surfaces (v), and load (w). A smaller number indicates more severe lubrication conditions.

The vertical axis shows the friction coefficient (μ).

As shown in the figure, the lubrication state between two surfaces in relative motion is divided into three regions:

The blue region on the far right is “fluid lubrication.” A sufficiently thick layer of lubricant separates the surfaces, preventing wear. This is the ideal lubrication state.

Conversely, the red region on the far left is “boundary lubrication.” Although lubricant is present between the surfaces, the film is thin, and microscopically, the peaks of surface irregularities make contact. This leads to wear and eventually seizure.

The yellow region in the middle is “mixed lubrication,” where both fluid and boundary lubrication coexist. The lubrication between piston rings and cylinder walls in reciprocating engines is said to be in this severe mixed lubrication state.

To improve fuel efficiency with engine oil, we aim for the minimum point on the Stribeck curve by lowering oil viscosity, as a lower friction coefficient is advantageous.

However, as the curve shows, this is a dangerous region where the friction coefficient rises dramatically with even a slight decrease in the Sommerfeld number!

To counter this, low-viscosity oils incorporate FM (Friction Modifiers) to aim for friction reduction effects.

While low-viscosity engine oils may yield fuel efficiency improvements, these gains are surprisingly small. Moreover, FMs are consumed during use. Undoubtedly, using engine oil with a viscosity that provides ample lubrication to delay wear is a kinder choice for the engine as a machine.

When manufacturer specifications no longer allow the use of 5W30 or similar engine oils, the legendary additive known as Maruyama Molybdenum might be a solution to improve the situation.

(To be continued in the next post)

Leave a Reply