As you know, the Jimny is a genuine cross-country 4WD with front and rear rigid axles and a ladder frame structure, despite its small body size.

Since the basic structure is authentic, various modification parts are commercially available to seek even greater off-road performance, and it’s not uncommon for owners to perform maintenance themselves.

This time, we received a request to replace the kingpin bearings.

This maintenance is to prevent issues such as “shimmy” or “death wobble” which cause the steering wheel to vibrate during high-speed driving.

In the structure unique to front rigid axle vehicles, a pair of opposing tapered roller bearings called “kingpins” are fitted on each side of the steering rotation axis.

Since steering, drive, and drive disconnection are concentrated near the hub knuckle, this is a structure not found in independent suspension front axles.

2015 model ABA-JB43W M13A 5MT Mileage: 101,000km

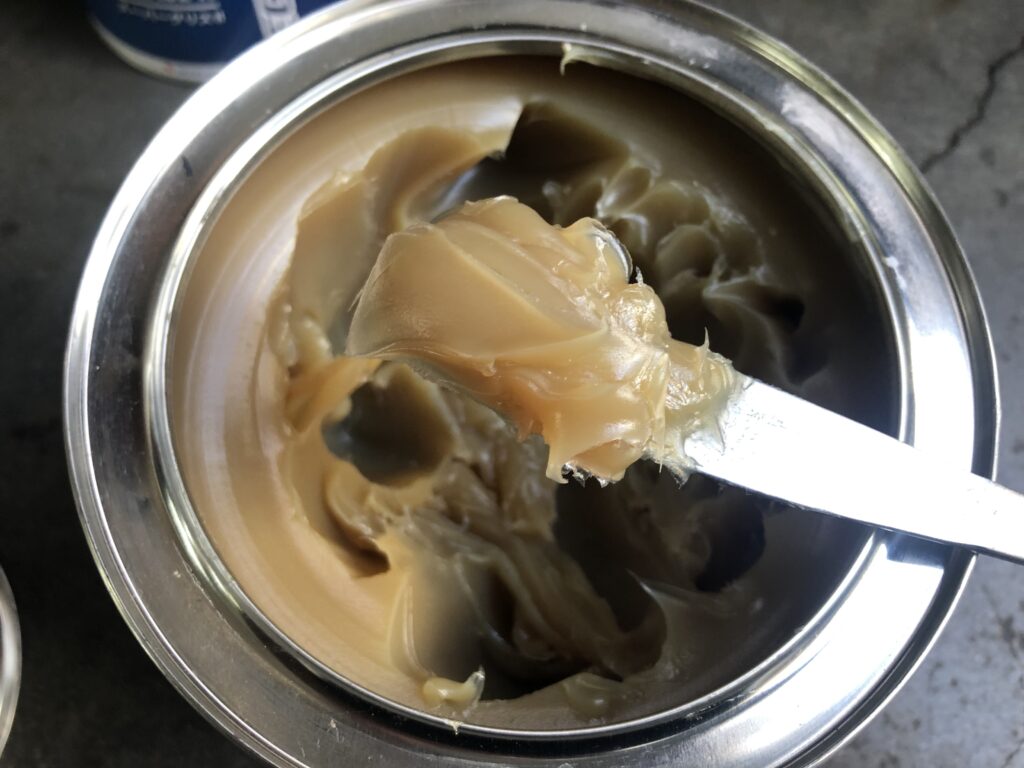

I apologize for the few photos, as I hesitated to touch the camera during the work that involved handling paste-like grease.

I watched several videos of regular people struggling with this task on video sharing sites. If you’re not used to handling grease, your hands, tools, and car will get covered in sticky oil, which can be quite overwhelming.

Well, I was initially smiling as I watched, thinking that getting dirty could be part of the “fun” of tackling such a project, but when I saw their haphazard technique for filling the bearings with grease, and the dangerous way they handled tools, I couldn’t continue watching. What I found particularly dangerous was the handling of the special tool for removing the rod end without taking safety precautions. I’m glad they weren’t injured, but I believe basic safety considerations are important, even when enjoying a hobby.

In another video, I was surprised to see someone using the “double hammer method,” which existed long ago as an emergency measure, to detach the same rod end.

This method involves placing two large hammers in series on the knuckle arm near the rod end, and using the principle of collision to apply impact, unlocking the tapered fitting through momentary elastic deformation.

The impression that using a large hammer to hit the center of the target and loosen tight fittings was “professional” is a thing of the past. I think there are no professionals who routinely use such methods anymore.

Now, the grease used this time was carefully decided after thorough discussion and consultation with the customer.

For the Birfield-type constant velocity joint inside the axle, we used Suzuki’s genuine Super Grease H, which the customer had researched.

For the area to be filled around the kingpin bearings and constant velocity joint, we chose TOYOTA’s multipurpose grease No.3.

TOYOTA Genuine MP Grease No.3 08887-00201 2.5kg

By the way, the service manual did not specify the filling method or types of these two greases.

The service manual is just a reference. It’s not uncommon for well-known information to be omitted, so if a general person follows this manual exactly, they might make mistakes (I thought the description for this particular part was excessively unhelpful).

What concerned me toward the end of the work was the liquid sealant on the kingpin mounting surface.

I noticed during the cleanup of residual sealant after removal that a liquid seal that dissolves in parts cleaner seemed to have been used during new vehicle manufacturing. It felt similar to hard butyl rubber.

The fact that it dissolves in parts cleaner suggests it might also dissolve easily in grease.

The frequent corrosion due to water ingress especially around the upper kingpin area might be due to inappropriate sealant.

Here, I used my favorite LOCTITE SI 5699 GREY.

It has excellent oil compatibility and is suitable for resealing the tapered transmission oil drain bolts often found in Suzuki vehicles. I started using it after learning that it’s easy to remove during re-maintenance and that it’s used in many domestic new car production lines.

LOCTITE Liquid Silicone Gasket Gray 5699 Liquid Packing 40ml

This time, I was reminded by the large number of videos that there’s a culture where regular people are deeply involved with their beloved Jimny. While I hope that experienced individuals use appropriate tools safely, and though I feel very reluctant to take away a young person’s dream, if there are elements of “inexperience” or “challenge,” I think it’s better to leave delicate areas like steering and drive systems to professionals.

Leave a Reply