Nowadays, independent suspension has become mainstream for vehicle suspensions, but for example, the rear suspensions of Suzuki and Daihatsu light commercial vehicles still use the traditional link-type rigid axle.

With fewer parts, a simple and sturdy design, it may still be the mainstream structure for cost-sensitive vehicles.

And the authentic cross-country JB43W Jimny Sierra that I worked on this time also has front and rear link rigid axles.

Since there is no steering mechanism on the rear side, the axle extending from the differential to the hub flange has an integrated structure.

I believe that high mileage, rough terrain driving, and installation of large diameter and heavy tires cause oil seal failure deep in the hub bearing, resulting in gear oil leakage. This washes away the grease inside the axle’s ball bearings, leading to poor lubrication and rumbling noises while driving.

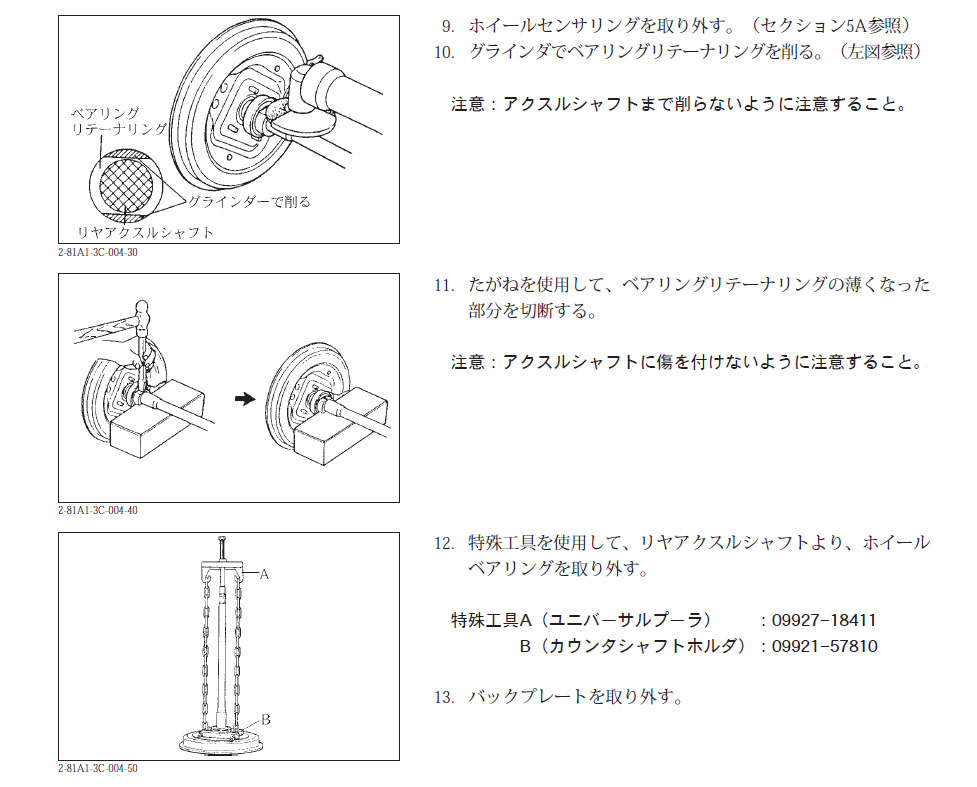

The photo above shows the ball bearing and retainer that were replaced with new ones during this job. They are press-fitted to the hub flange side of the axle shaft, and recently, many have the ABS sensor gear integrated with the retainer.

While the inner bearing isn’t so difficult, the retainer is fitted to the shaft with a strong force of about 5 tons during press-fitting, so removal is not easy.

Even in the maintenance manual that describes standard procedures, primitive methods like grinding with a grinder and splitting with a chisel are recommended.

However, this cutting work is quite risky and laborious.

When I looked for other safer and smarter working methods, I found that tool manufacturers sell commercially available attachments with an imposing appearance like a mortar, but the frequency of the work and the price are completely disproportionate.

Hasco Rear Shaft Bearing Puller HRBP-869S

On the other hand, for extracting the relatively weakly press-fitted ball bearings, Suzuki genuine SST (Special Service Tools) are available at a reasonable price as shown in the illustration above.

Previously, I used to cut the ball bearings as well, resulting in a series of dangerous operations to remove parts press-fitted onto a single axle shaft.

I prepared the genuine tools hoping for a safer operation, but when I followed the illustrated procedure of hooking onto the counter shaft holder bolts, the bolts deformed due to insufficient strength.

It was a questionable result that made me wonder if the technical staff who designed the SST had verified this operation.

Let’s look for another method.

I welded a hook to a scrap bearing race of appropriate size.

Furthermore, I welded this homemade attachment to the outer circumference of the bearing to be extracted and attached it to a chain puller.

For the next operation, I will weld the bearing to be extracted to this one, so the trophies will pile up like pieces in a daruma otoshi game (laughs).

|

|

![[商品価格に関しましては、リンクが作成された時点と現時点で情報が変更されている場合がございます。] [商品価格に関しましては、リンクが作成された時点と現時点で情報が変更されている場合がございます。]](https://hbb.afl.rakuten.co.jp/hgb/0f278a59.8ba48eb1.0f278a5a.e5f09e21/?me_id=1198680&item_id=11903375&pc=https%3A%2F%2Fthumbnail.image.rakuten.co.jp%2F%400_mall%2Ftuzukiya%2Fcabinet%2F0%2F0%2F4505%2Fh125-0030.jpg%3F_ex%3D240x240&s=240x240&t=picttext)

Leave a Reply