A Honda N-WGN brought in for its 24-month inspection (Japanese vehicle inspection) had its engine warning light (and, by design, the Vehicle Stability Assist warning light) illuminated since it was purchased as a used car about two years ago. This condition would not pass the current periodic inspection.

There were signs that the vehicle had been used in areas where de-icing agents are spread, and I was informed that the engine oil change management hadn’t been particularly good. The customer felt that as a used vehicle, it offered sufficient cost performance for their intended use, and they desired improvements to pass the inspection within a reasonable budget.

Apparently, they had the warning light diagnosed at an authorized Honda dealer right after purchase. They were told that an abnormal phase deviation of the rotation axis inside the engine, namely an abnormal valve timing, was detected, with multiple potential causes.

The warning light, which had been cleared during the diagnosis, reportedly relit by the time they reached the next traffic light after leaving the dealership.

Repairing a rotational phase deviation abnormality, if it’s a mechanical issue, typically involves relatively extensive disassembly work.

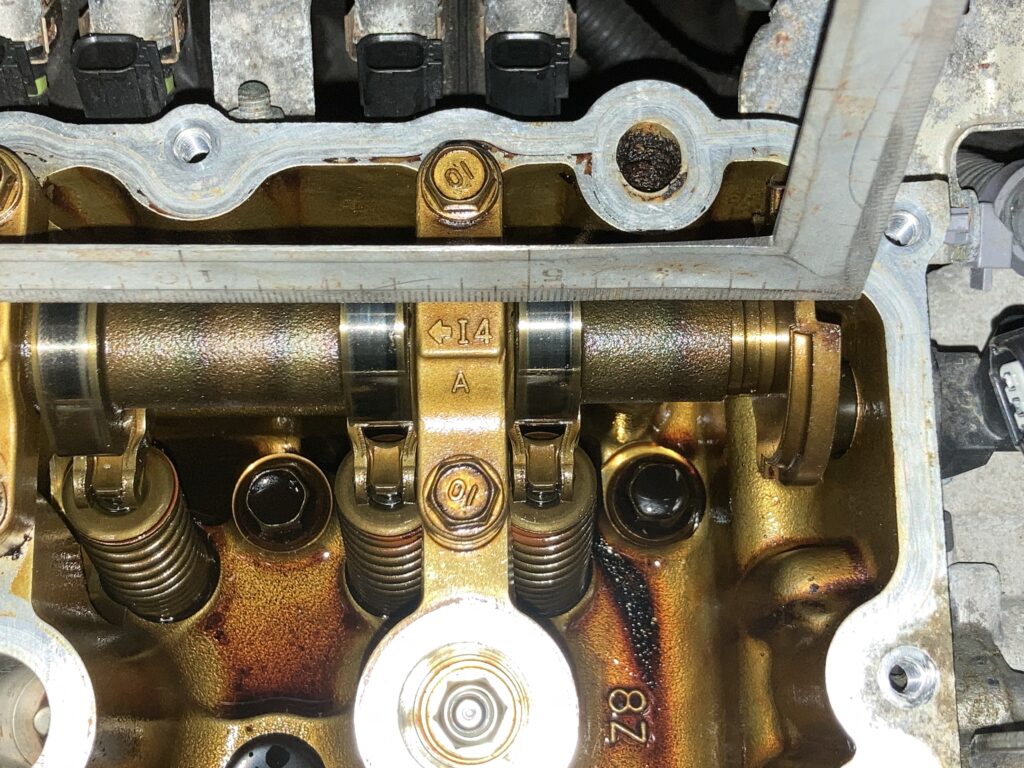

For now, I opened the valve cover, but the state of engine oil change management wasn’t as poor as I had been led to believe.

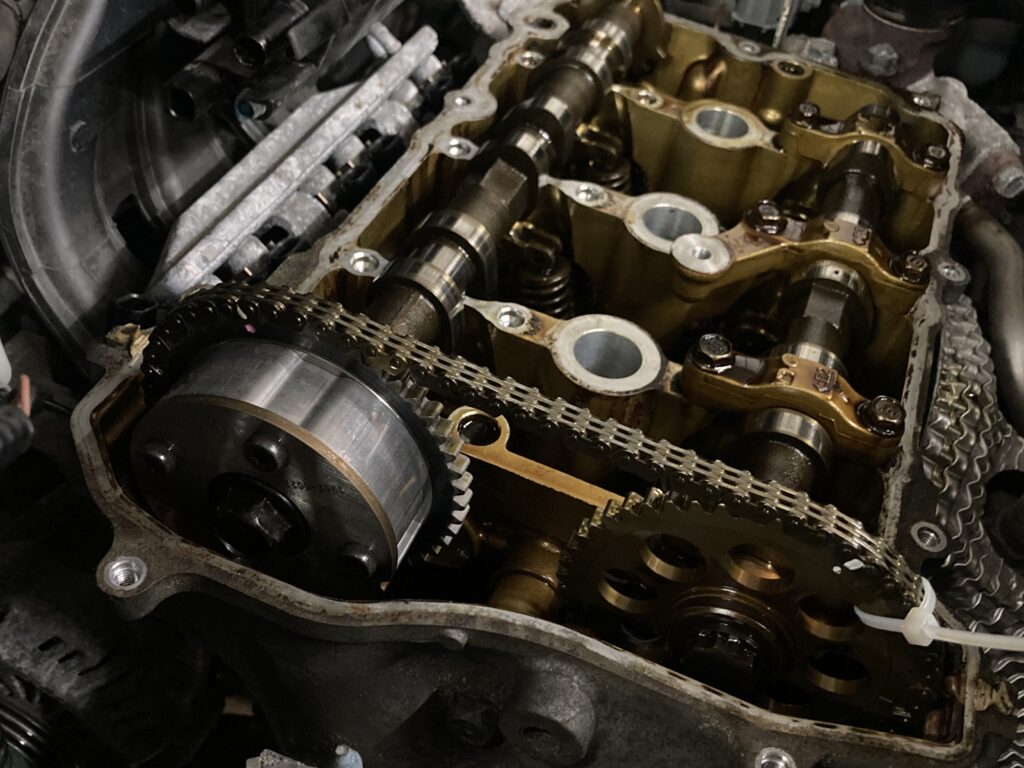

Rotating the crankshaft showed normal valve timing. The timing chain was also in good condition. Of course, I confirmed the normal operation of the oil control valve as well.

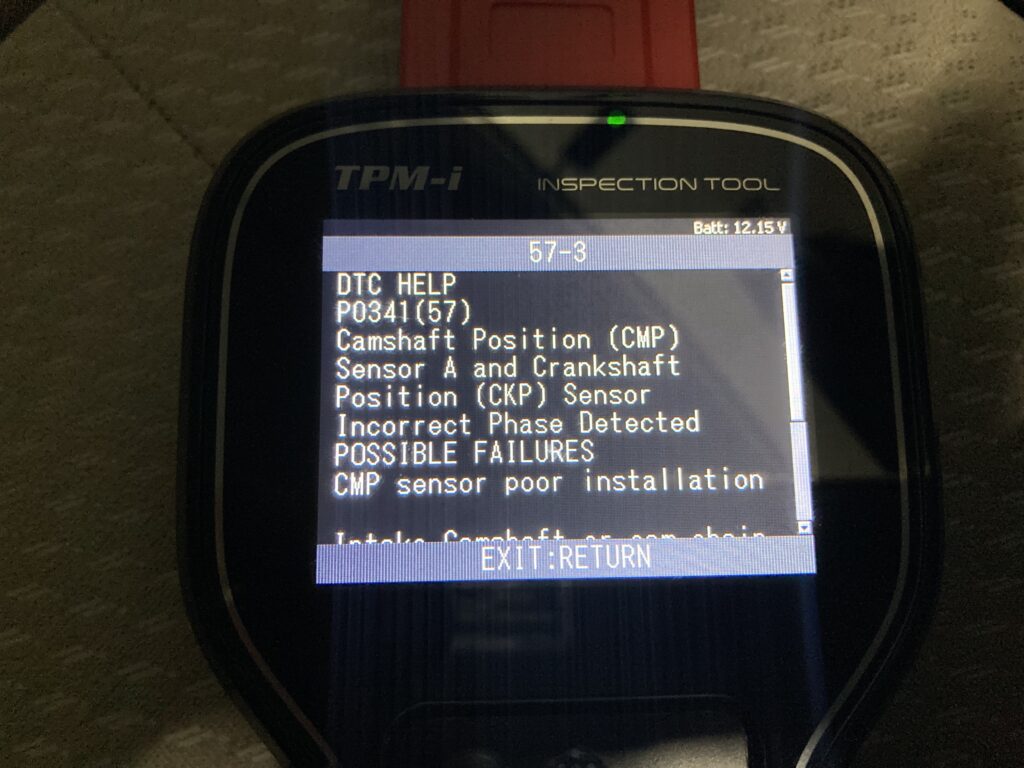

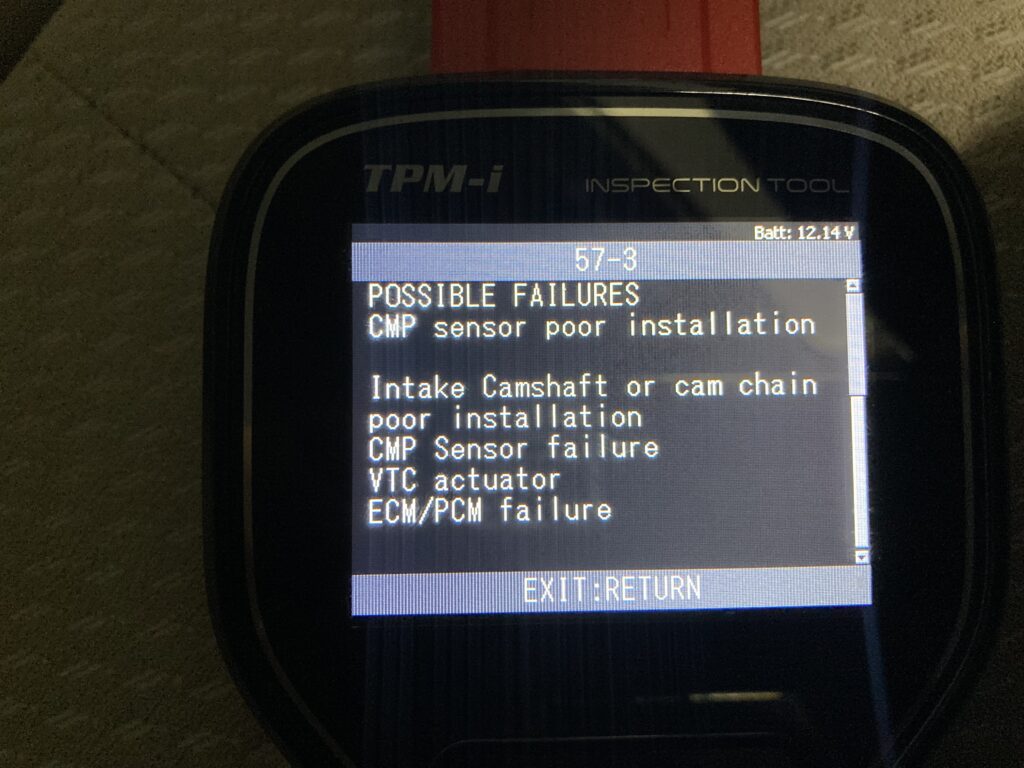

Then, I checked the detected Diagnostic Trouble Code (DTC) with a simple diagnostic tool.

As reported, it was Honda code 57-3, common code P0341, indicating a rotational phase deviation detected between the camshaft position sensor (referred to as TDC sensor in Honda terminology) and the crankshaft position sensor.

The developer’s estimated locations aren’t very reliable, but I reviewed them for reference.

Web searches are useful for actual failure cases, and surprisingly, I found that the sensor plate (TDC sensor counterpart) press-fitted to the rear end of the intake camshaft can rotate and shift (!) out of position.

The mechanic who encountered this case speculates that the cause might be the mating of the sensor plate and camshaft without any rotation stopper. Due to the difference in materials, thermal expansion ratios differ, and in cases of poor oil change management, overheating can cause it to loosen.

The mechanic kindly photographed and shared the shifted state of the sensor plate compared to a new camshaft. I referred to two such cases. Interestingly, the direction of shift in each case was about the same degree but in opposite directions. When compared side by side with a new camshaft, the amount of shift was easily visible.

However, when I checked the sensor plate shift on the N-WGN’s camshaft using a straightedge, I couldn’t visually detect any significant difference compared to the new camshaft images posted online.

This led me to wonder if there might be an issue with the VTC (Variable Timing Control) actuator operation, which makes an unpleasant “clatter” sound at engine start, causing it to fail diagnostics. The Honda service manual does list this as a potential cause for DTC detection.

It mentions “VTC actuator sticking” and “VTC actuator malfunction.”

Note that for the sensor plate shift issue found in online failure cases, there are no standards or inspection methods provided.

Since we’re exploring possibilities, let’s proceed one step at a time.

I installed a new VTC actuator.

The first few engine starts with the new VTC produced some noise, but after a while, it settled into a smooth engine start sound, raising my hopes.

However, the DTC is only not stored when the engine is warm. When cooled to room temperature, it stores the same DTC, 57-3 (P0341).

Honda’s system for this DTC illuminates the warning light when a failure is detected in two consecutive drive cycles (defined as one ignition ON to OFF cycle including engine start, hereafter D/C). The light turns off after three consecutive normal D/Cs. Therefore, there may be cases where the DTC is stored but the warning light isn’t on, and the driver might not notice the malfunction.

Although I replaced the VTC actuator, while there was some improvement, it wasn’t completely fixed.

So, what about the TDC sensor, the next suspected component? The Honda service manual only mentions “characteristic deviation” as a possibility, with replacement being the only practical inspection method.

Contrary to expectations, replacing the TDC sensor with a new one reverted the condition to how it was when I first received the car – storing DTCs regardless of engine temperature.

Summarizing the changes after replacing these two parts: The root cause of the DTC detection hasn’t been eliminated, and it seems to be an abnormality very close to the DTC judgment threshold, making it extremely sensitive.

I’ve taken a roundabout way, but suspicion has narrowed down to the sensor plate at the rear end of the camshaft, as seen in the two online cases.

Reviewing the service manual again, I found that the phase deviation abnormality is judged when it’s 10° or more for 4.0 seconds or longer. This 10° refers to the crankshaft rotation; for the camshaft we’re focusing on, it’s half of that, 5°. On the circumference of a 50mm diameter sensor plate, this translates to about 2mm.

It was unrealistic to try to visually judge this based on the comparison images posted online using the round cam lobe end as a reference.

Since the VTC actuator replacement improved both the knocking and drivability from when I first received the car, I hesitated to incur further costs just to turn off the warning light, considering the overall condition of the vehicle. However, the owner agreed with my curiosity, and I continued the work.

I ordered a new camshaft.

Here are the sensor plate sides of the old and new camshafts. There’s a stable position (shape) like this. To make it easier to visually judge the approximately 5° shift we estimated, I

attached the larger diameter VTC actuator on the opposite side for comparison.

With this comparison, visual judgment became easy, and measurements confirmed the expected 5° shift (by the way, the VTC actuator is in the most retarded position).

The DTC is no longer stored. While knocking still occurs under limited conditions, if carbon buildup in the combustion chamber is the main cause, it should improve significantly with the injection of high-octane fuel. Please check the condition after returning the vehicle.

For reference, I removed the sensor plate. The mating without any rotation stopper indeed feels unreliable.

Leave a Reply