I first received a consultation about an ineffective air conditioning system exactly three years ago.

Although Subaru’s in-house production of the iconic Sambar ended quite some time ago, I hear that the truck, van, and wagon versions of this model remain extremely popular.

The Sambar in question, which had been purchased used just before the consultation, had a surprisingly low mileage of around 50,000 km and appeared to be in good condition. At first glance, I didn’t expect it to have air conditioning issues.

Specifications: 2010 model, EBD-TV2, EN07 engine, 5MT, odometer reading 74,000 km

Upon inspection from under the vehicle, I noticed two cooling fans side by side, with the larger one not spinning when the air conditioning was on.

According to the service manual, both fans should be running when the air conditioning is active. With only the smaller fan operating, the condenser cooling would be insufficient, matching the symptom of ineffective air conditioning.

However, it seemed unlikely for a fan motor to fail at just around 50,000 km.

I performed an individual component check.

Those experienced in servicing Sambars would understand that its serviceability is comparable to, or in some areas worse than, imported vehicles. Just to access the fan motor connector for individual testing, I had to insert my arm up to the elbow through intricately arranged water hoses, scratching my arm in the process.

Nevertheless, I managed to disconnect the connector and connect test leads to both the fan motor side and connector side. When I directly applied power to the fan motor, it didn’t move, but voltage measurements at the vehicle-side connector showed that fan motor drive voltage was present.

These results would typically indicate a faulty fan motor, but when I accidentally touched the power lead connected to the fan motor, it suddenly started with a snap.

After that, the fan continued to operate normally, so I reconnected the vehicle-side connector and observed proper fan operation for a while. Still perplexed, I returned the vehicle without any further action.

However, a month later, the same symptom recurred, and the vehicle was brought back.

Based on the previous inspection results, I diagnosed the larger fan motor as faulty and, with approval, replaced it.

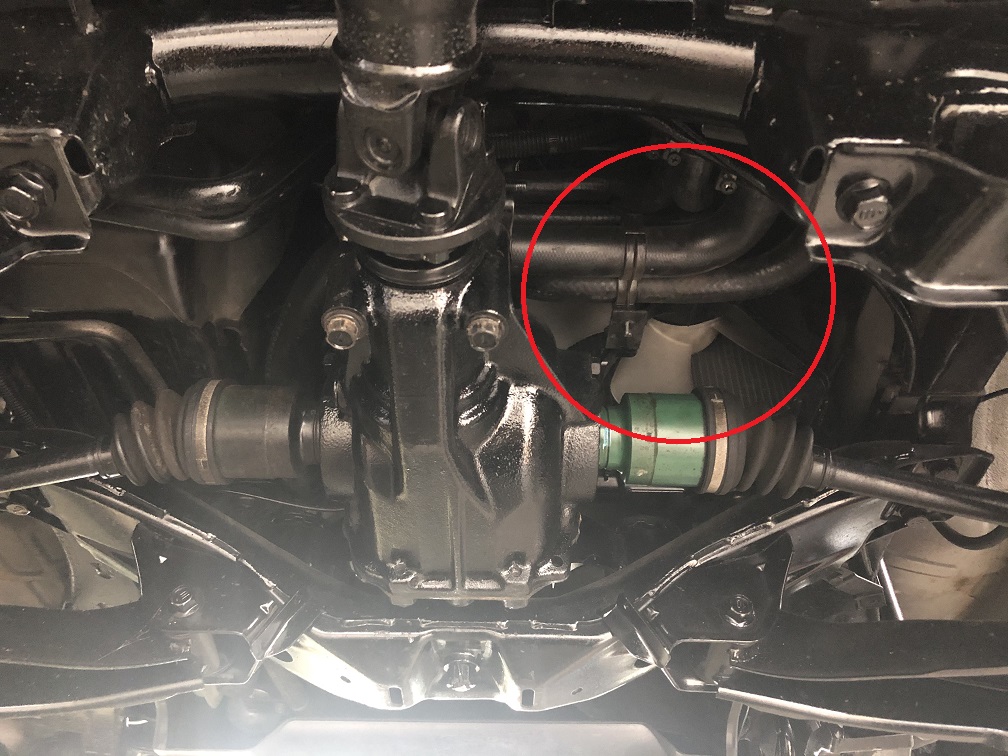

The target fan motor is located in the area circled in red. For 4WD models, the front differential must be lowered to replace the fan motor.

Accessing the bolt in the upper right of the fan shroud is particularly challenging, but a small, thin tool can reach it through a narrow gap in the right front wheel well.

Other manufacturers’ similar models often have radiator areas located under large interior openings or behind easily removable front bumpers, making replacement less troublesome. The Sambar, however, only has a small service hole in the interior, allowing little more than battery and radiator cap replacement. Its body structure, with the cabin mounted on a ladder frame, differs significantly from other manufacturers’ monocoque designs. While I can’t fathom all the reasons, I assume various factors led to this troublesome layout.

This time, we only needed to detach the differential for the large fan replacement, but radiator replacement would require detaching the entire front suspension. I often wish it had a tilting cabin structure like large trucks, which would be much kinder to mechanics.

After installing the new fan motor, the air conditioning worked smoothly. When I disassembled the motor deemed faulty, I found no signs of worn brushes or a burned shaft.

Although I wasn’t entirely satisfied, I returned the vehicle to the customer, and it operated smoothly for a long time. However, surprisingly, three years and 24,000 km later, the air conditioning problem recurred.

Evidently, the root cause had not been eliminated.

This time, neither of the two fan motors was running. I decided to re-examine the larger fan motor that I had serviced three years ago, along with its connections.

Three years ago, I had connected test leads by feel in an invisible location. This time, to visually inspect the connector’s condition, I routed the vehicle-side connector to the small service hatch under the passenger seat.

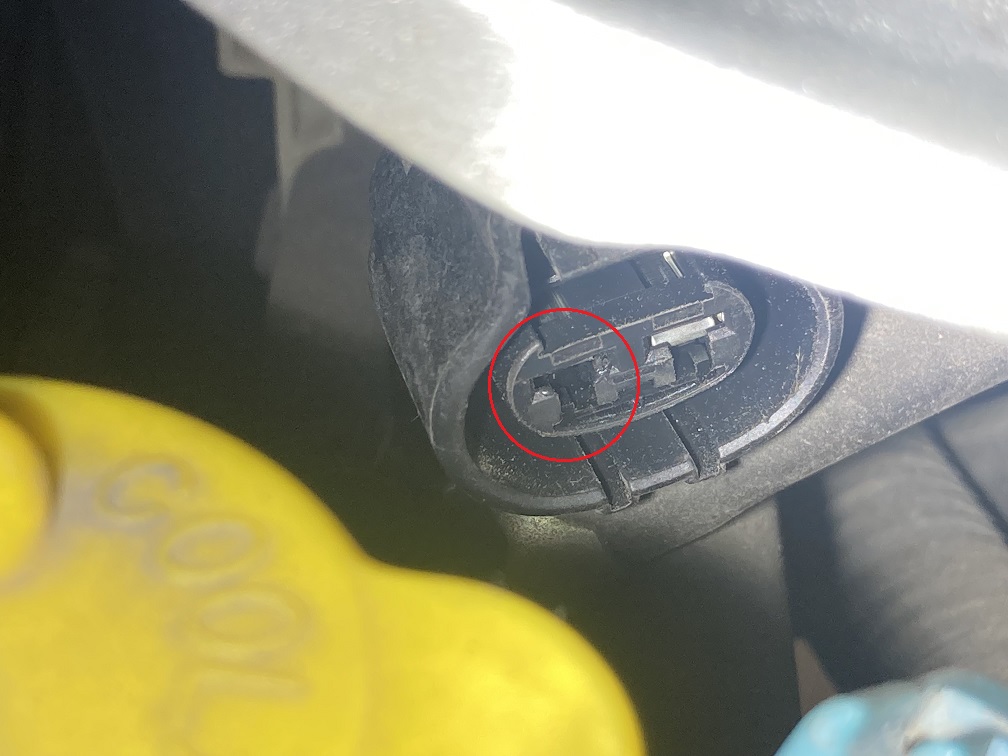

I noticed that the metal terminal on the left side was recessed.

Looking closely at the fan motor-side connector that I had replaced three years ago and kept out of lingering concern, I saw slight burn marks on the tip.

It’s highly unlikely for a domestic vehicle to have insufficient current capacity in the connector causing overheating. I surmised that the vehicle-side connector terminal was insufficiently inserted during manufacturing, resulting in a shallow, loose connection with the fan motor-side terminal, leading to poor contact.

The new surface of the new fan motor’s terminal likely allowed for smooth operation for three years and 24,000 km.

This inspection revealed internal melting of the vehicle-side connector, necessitating connector housing replacement. However, this usually requires replacing the entire wire harness, which is impractical for repair.

After some searching, I fortunately found an identical Toyota genuine part.

I reused the undamaged connector terminal. I wanted to avoid changing the standard length of the wiring near the rapidly spinning fan.

Unable to photograph the wiring repair in the tight space, I’ll demonstrate the repair process outside the vehicle.

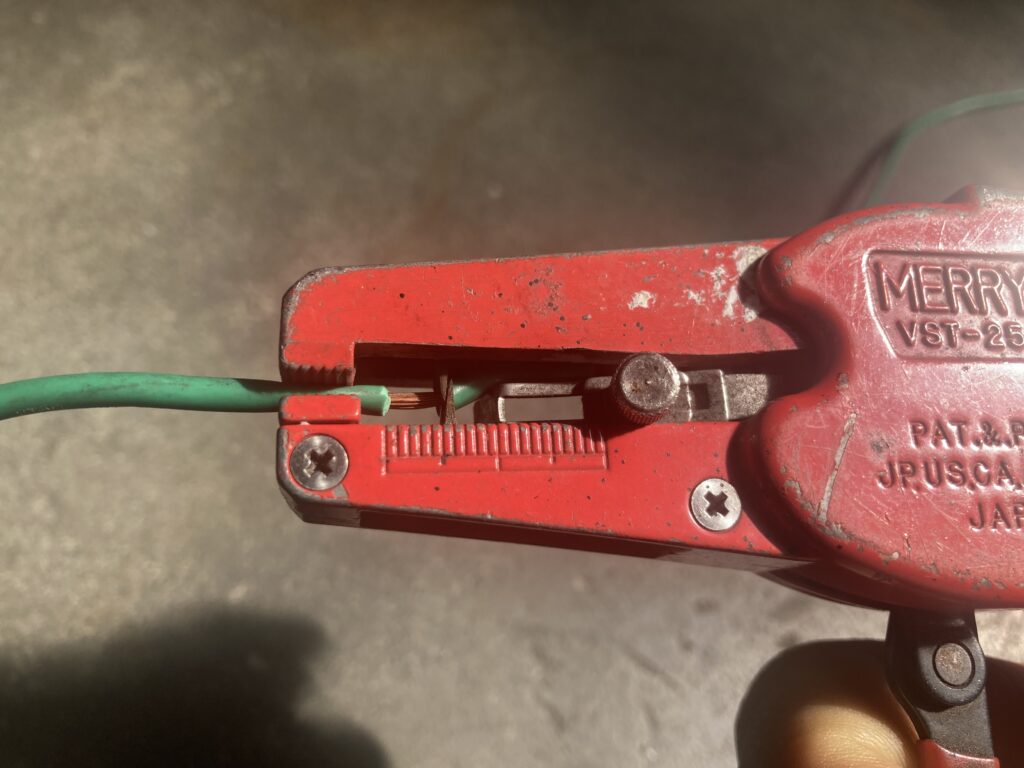

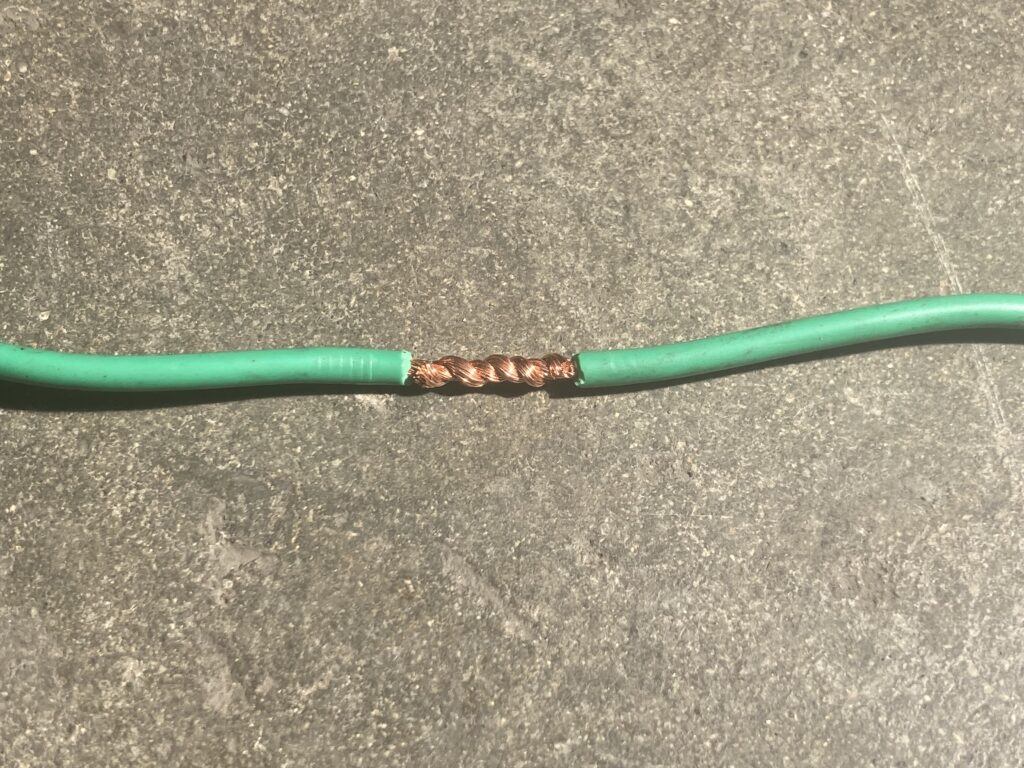

When connecting cut wires like this, first strip an appropriate amount of insulation with wire strippers.

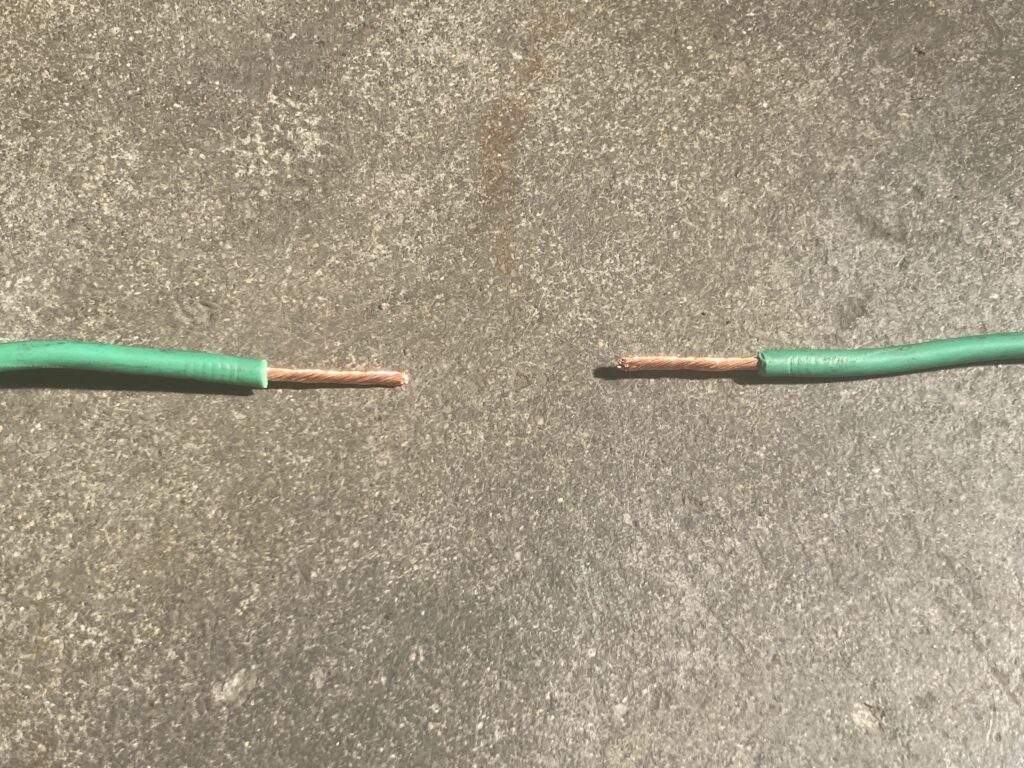

Twist the bare wire in the same direction.

Then, twist the bare wires together in the opposite direction, like making a straw rope.

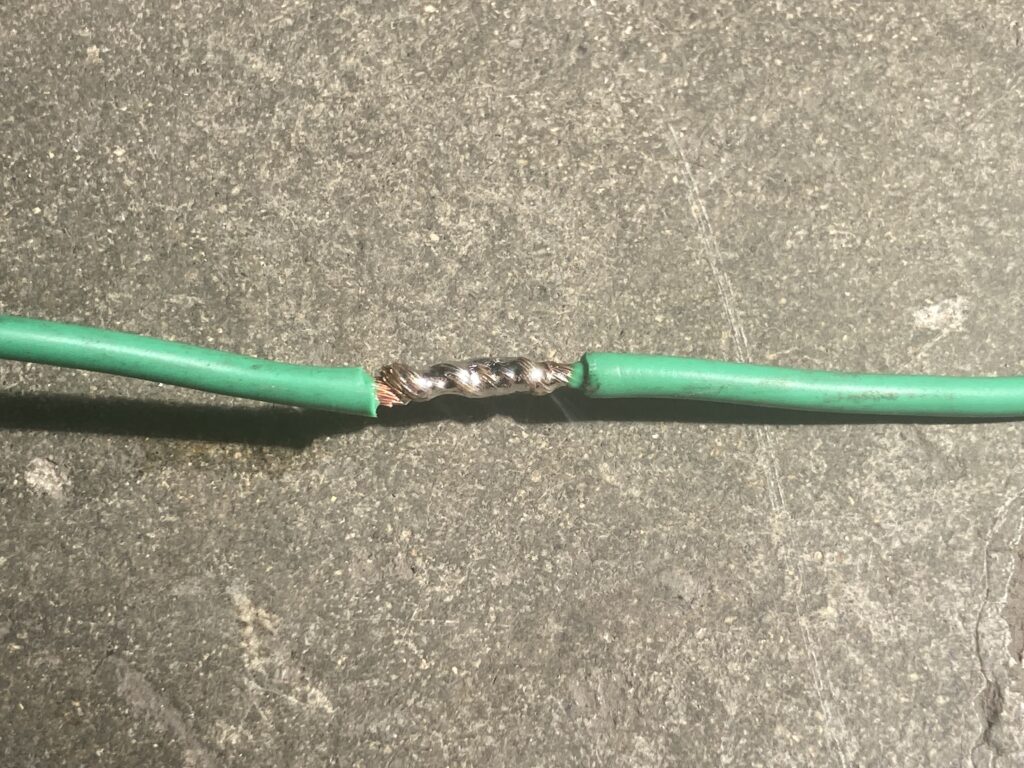

Quickly apply solder with a relatively high-wattage soldering iron.

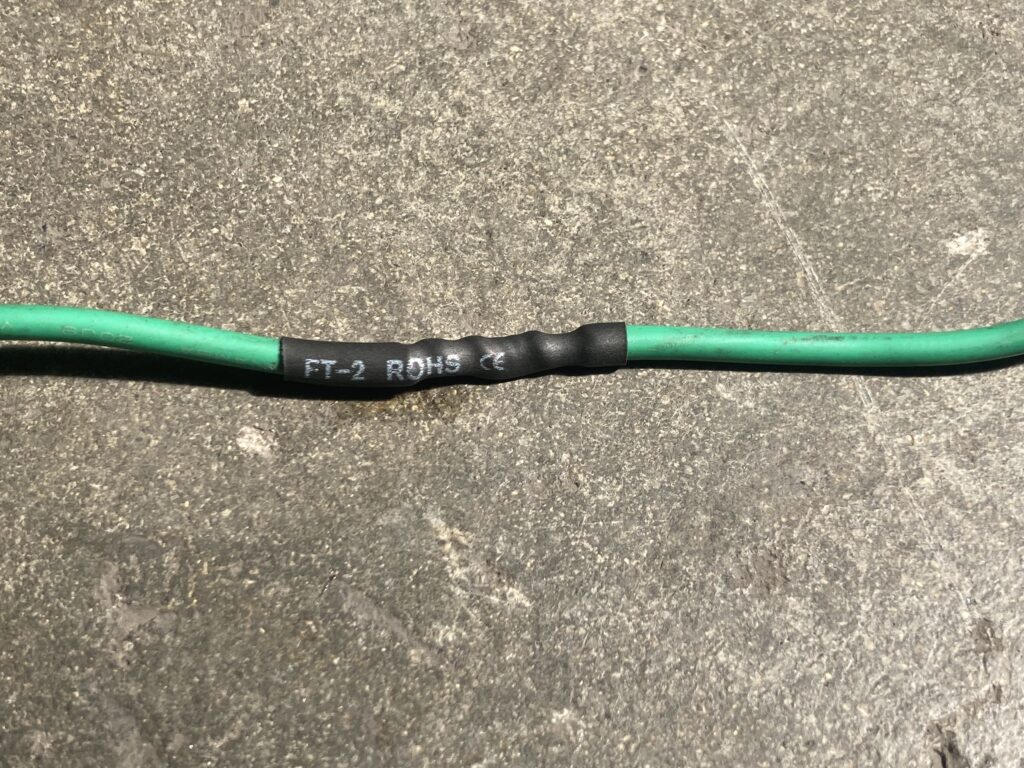

Insulate with heat shrink tubing that was pre-threaded onto the wire.

As for the smaller fan motor’s operation, it would run smoothly when given a shock and didn’t stop during our possession of the vehicle. Since the smaller fan motor’s connector is located further from the hard-to-reach fan motor, it’s more likely a motor issue than a connector contact problem. I believe it’s simple wear due to extended operation time compensating for the large fan.

With the large fan operating normally, both the air conditioning and engine temperature control work fine. We’ll continue to monitor the operation of both fans with the customer and plan to replace the radiator simultaneously when the time comes to replace the small fan motor.

Leave a Reply