In the tough work of car maintenance, which leaves hands covered in oil, arms full of scratches, and requires long hours in uncomfortable positions, good “maintainability” is a very important factor.

For us mechanics who engage in maintenance work every day, it’s a joyful moment when we can feel the kindness and consideration of the engineers.

When I mainly work on Japanese cars, despite the hardships, the work progresses without any particular delays, and it’s easy to feel like that’s the norm. However, when dealing with imported cars, especially Italian ones, I often find myself gnashing my teeth at the difficulty of the work. I realize that the layout and structure of Japanese cars are the result of highly advanced technology, the efforts of engineers, and the culmination of compromises between engineers.

Now, about the Daihatsu Mira that was brought in for a clutch noise issue. After some research, I found that problems with the clutch cover strap belt breaking are not uncommon, so I immediately removed the transmission from the vehicle to check the main clutch parts between the engine and transmission.

MY2005 TA-L250S EF-SE 5MT with 107,000 km on the odometer.

In the case of this vehicle, it is spatially possible to remove the transmission alone. If the transmission has to be removed together with the engine, the number of replacement parts for liquid-carrying pipes and the work time would increase, so I want to avoid that if possible.

The engine and transmission block is fixed to the vehicle at three mounting parts, two of which are connected to the transmission. When removing the transmission alone, the remaining one is insufficient to support the weight of the engine, so this time I used the prop rod shown in the photo to stabilize the engine’s position until the transmission was fully reinstalled.

For safety, I used a transmission jack to lower the transmission body from the vehicle, but since the weight is light, it can be handled sufficiently with human power alone.

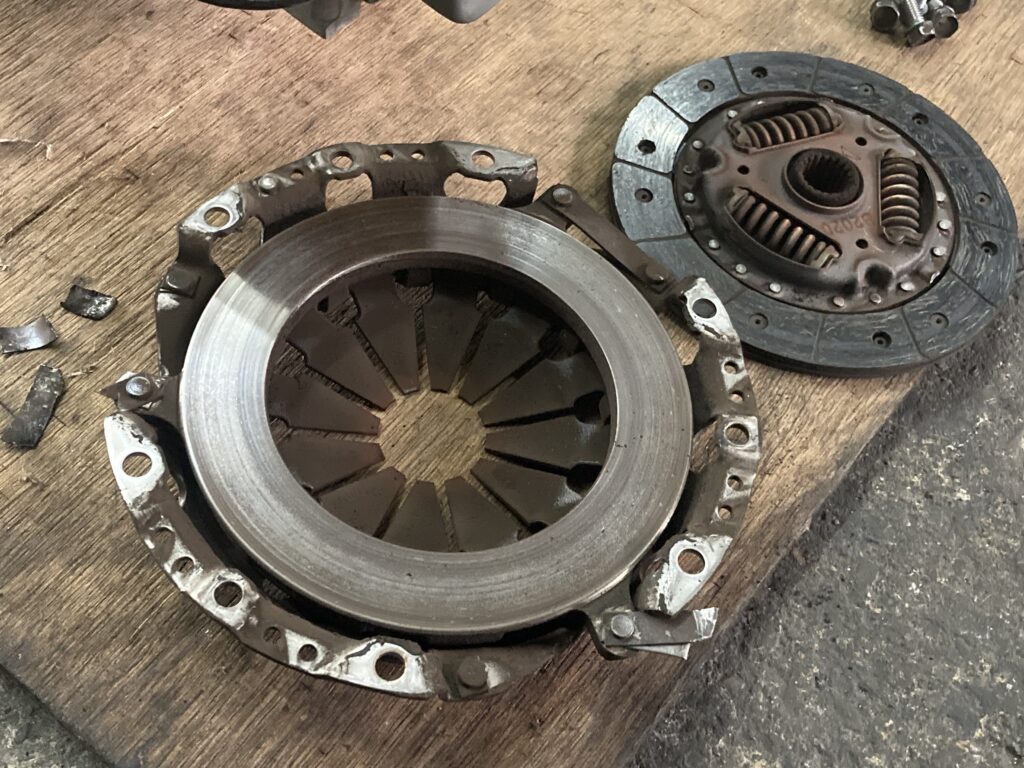

When the connection between the transmission and engine was released, fragments of the strap belt fell off with a clatter.

Looking at the clutch cover, I found that two out of three straps were broken.

Rather than a lack of strength, it looks like metal fatigue due to resonance. Since I feel a slight weakness in the engine mounts even when new, there may be some interaction with engine oscillation.

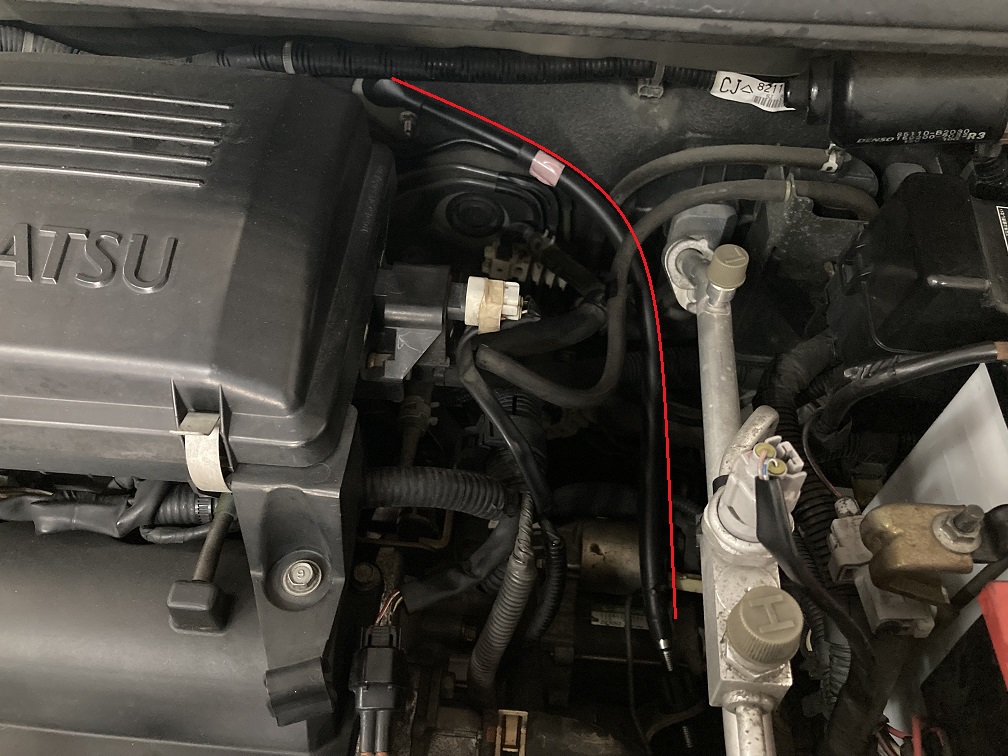

Since I’m at it, I’ll replace the clutch operating wire at the same time.

The layout in the engine compartment is as shown by the red line, with one end connected to the transmission lever and the other passing through the bulkhead (the partition between the engine compartment and the passenger compartment) to the clutch pedal.

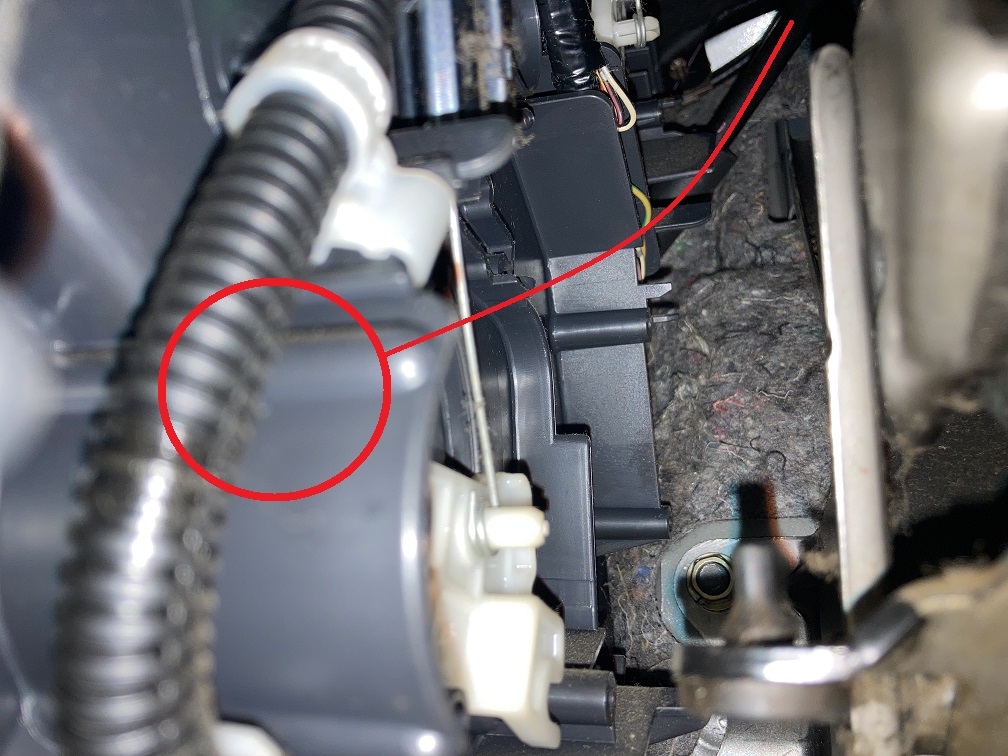

I thought the wire replacement would be simple, but I was surprised when I looked at the interior side.

The wire is located in the small space between the large air conditioner housing at the foot and the bulkhead, and in a deep part. It cannot be directly visually confirmed. The red circle in the back of the air conditioner housing is where the wire penetrates from the engine compartment to the interior.

For a moment, I considered the heavy work of completely removing the dashboard and air conditioner housing, but I calmed down and checked the maintenance manual.

There, I found a careful diagram and detailed work procedures. Perhaps because it was a vehicle developed in an era when manual transmission cars are disappearing, the maintenance manual showed evidence that engineers, in the limited space given to MT cars, had used their fingers and tried various things in painful positions, just like us mechanics.

Even following this method, it’s a bit of a struggle, but I have the confidence that the work is possible, and I feel a sense of solidarity in sharing the hardship, so my peace of mind is completely different.

With the work completed, the small manual transmission car descends to the ground, and the properly functioning clutch engagement and the moderation of the gear shifting bring the car and driver even closer together, making the operation feel comfortable.

I would be happy if this charming lightweight MT car, which is rarely seen these days, is cherished by its owner.

Leave a Reply