We received this Daihatsu Move with the complaint that the engine warning light comes on occasionally, but there are no noticeable performance issues.

2008 model year DBA-L175S KF-VE 4AT mileage 100,000km

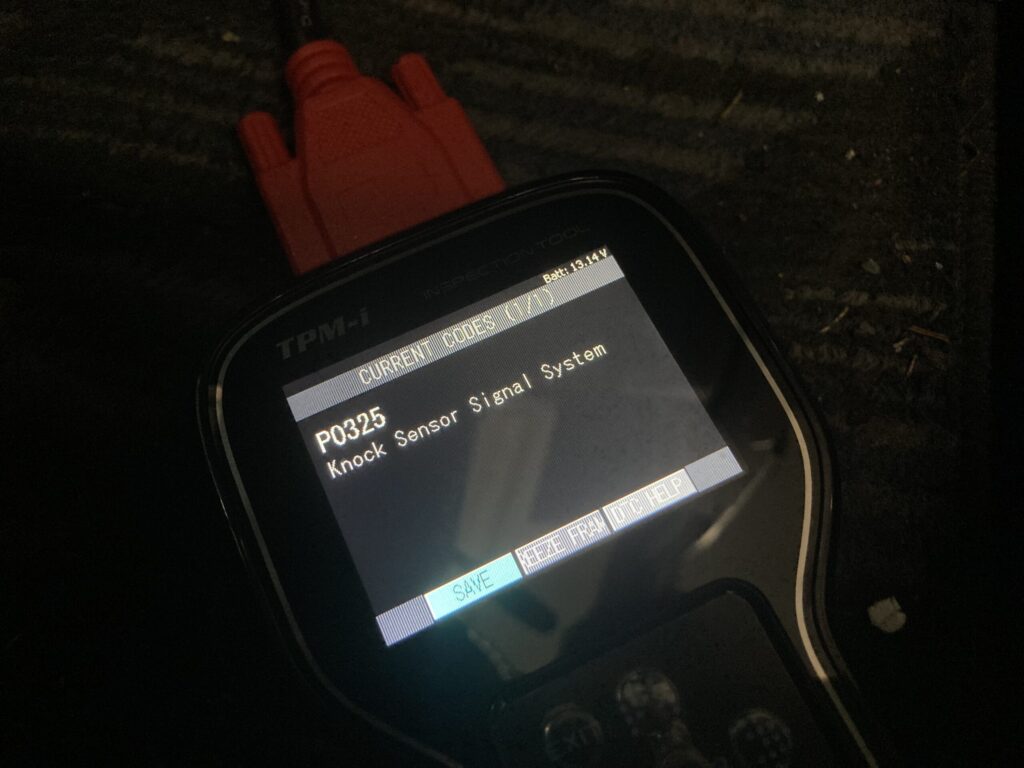

When we immediately checked the error code with a simple scanner, it showed P0325 knock sensor system.

The knock sensor is a sensor that detects knocking (abnormal combustion) that occurs inside the engine. It’s often misunderstood, but knocking refers to the metallic “rattling” sound of the engine, not the jerky movement of the vehicle. It occurs when the air-fuel mixture in the combustion chamber ignites spontaneously at times other than the normal ignition timing, causing the piston to receive force in the opposite direction during the upward stroke, causing it to shake and hit the cylinder wall.

|

|

The main role of the knock sensor is to detect these abnormal vibrations inside the engine, and the Engine Control Unit (ECU) adjusts the ignition timing to prevent knocking. When the knock sensor detects an abnormality, the ECU controls the ignition timing in a retarded direction. This is a setting that prioritizes safety even at the slight expense of engine output. It plays an important role in protecting the engine while maintaining optimal fuel efficiency and output.

When the knock sensor is not functioning, the ECU switches to a preset safe-side ignition timing. The reason you don’t feel any performance issues even when the warning light is on may be because the system enters fail-safe mode, and since knocking is unlikely to occur during normal city driving, the effects of the sensor abnormality are less likely to surface.

While it’s possible to drive with the warning light on, leaving it unattended for a long period may lead to deteriorated fuel efficiency and increased engine load, so early treatment is ideal.

The knock sensor, which is directly mounted to the cylinder block as shown in the photo below, is located in a somewhat troublesome location in the case of this Move’s engine.

On the transversely mounted engine’s bulkhead (partition between passenger compartment and engine compartment) side, it’s obstructed by the alternator and starter, not allowing for easy replacement work (below are the alternator and starter that were removed to access the knock sensor).

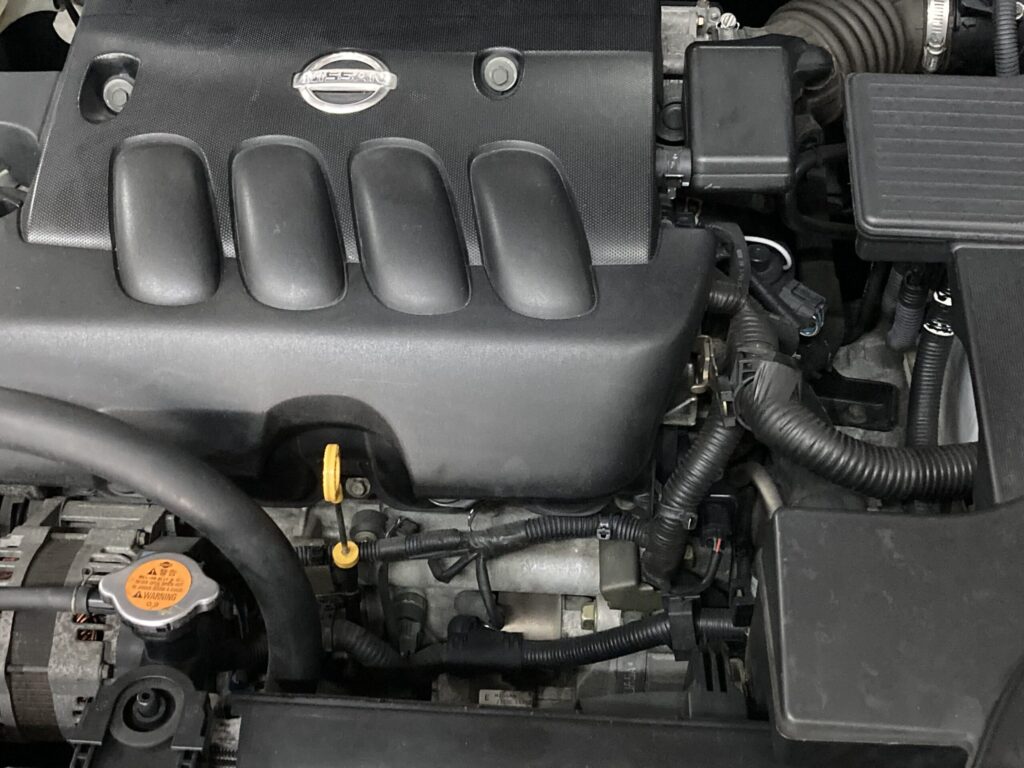

Ironically, knock sensors in such cramped locations are statistically more prone to failure, perhaps due to greater heat effects, while types that are easily accessible like the Nissan MR20DE engine shown next rarely malfunction.

Leave a Reply