Suzuki’s mild hybrid system primarily consists of an ISG (Integrated Starter Generator, an alternator with motor function) and a lithium-ion battery.

Its main feature is the ability to improve environmental performance efficiently while keeping costs down by adding relatively small electric parts to existing engines. It is particularly effective in improving fuel economy compared to engines alone during frequent starts and stops in urban driving. Additionally, the lithium-ion battery is placed in unused space under the vehicle’s seat, allowing you to enjoy the benefits of the hybrid system without sacrificing interior space or cargo capacity.

The ISG looks similar to an alternator except for its size and is mounted in a similar position, but it’s not just an auxiliary device—it’s legally recognized as an important power source component. Therefore, in the vehicle inspection certificate, the ISG electric motor model is listed alongside the conventional engine model in the “Engine Model” section.

This engine model listing is not just a formality but an important element related to the vehicle’s legal classification and associated tax benefits. It serves as the basis for receiving eco-car tax reductions and automobile tax reductions, and is a condition for being officially certified as a hybrid vehicle.

This ISG functions as a generator during normal driving. During deceleration, it recovers energy through regenerative braking and stores it in the lithium-ion battery. This stored energy contributes to improved fuel economy and reduced emissions by functioning as a power source that assists the engine power during acceleration.

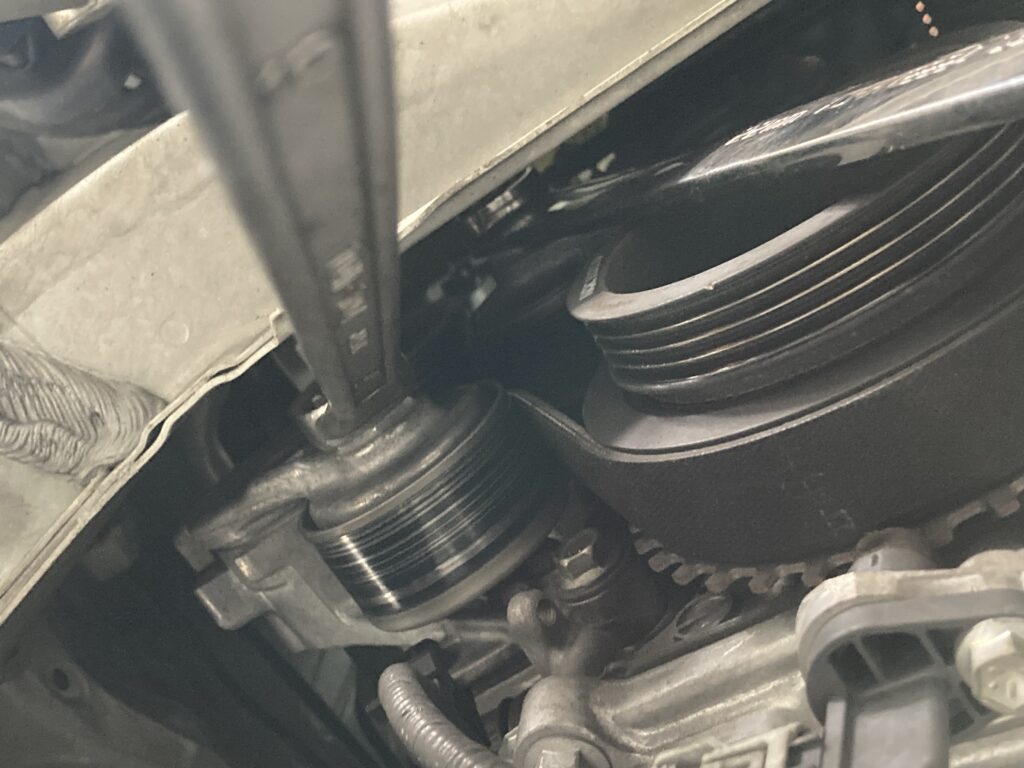

Also, during engine restart after idling stop, it turns the crankshaft through the drive belt we’re replacing today, eliminating the jerky operation common in typical kei car idle-stop vehicles during idle-stop and restart. This shortens the time to restart and enables smoother starts, reducing driver stress and improving usability.

The ISG performs various functions, and its drive belt does more work than belts that merely distribute engine power to drive the alternator. I was surprised to see such deterioration in a wide belt with 6 ribs made of recently improved belt material at this mileage.

2019 Model DAA-MK53S R06A-WA05A CVT Mileage 72,000km

There are two types of ISG belt tensioners: one with a single hydraulic tensioner and another with two spring-type tensioners like the one in this case.

For the former type with hydraulic damper tensioner, elaborate SSTs (Special Service Tools) are specified for belt replacement, but:

We know that it’s possible with general-purpose tools if you understand the structure and proceed carefully.

For the latter type in this case, KTC also offers special tools, but with some ingenuity, they weren’t particularly necessary without affecting work quality or safety.

On the other hand, I consider SSTs ideal and essential for removing and installing the accessory belt (for air conditioner compressor, water pump drive) stretch belt that goes around the outside of the ISG belt.

The non-adjustable belt is removed with this specially shaped genuine SST.

For installation, it is specified to use two types of SSTs (the embossed letters of belt manufacturer BANDO are visible), but since the space is tight and it is often difficult to work according to specifications, I work with only the larger SST (Is it really possible to fit two SSTs in this narrow space as per the service manual??).

As you become more experienced, this work can be completed in about half the standard time.

Leave a Reply