A Subaru Sambar, which had undergone repairs for cooling system issues (cooling fan malfunction) spanning several years, had been running without problems for five months after replacing the smaller cooling fan motor, as mentioned in a previous article. This resolved both air conditioning and engine cooling issues.

Vehicle details: 2010 EBD-TV2 EN07 5MT, mileage: 79,000 km

However, despite the cold weather in December, the owner contacted us saying, “Now the cooling fan won’t stop running.”

Initially suspecting welded contacts in the fan relay (which wasn’t replaced simultaneously), I learned that the fan operation stops after the engine is turned off. When driving resumes, the smaller fan starts, followed by the larger one, continuing until the ignition is turned off.

Given the busy year-end period and the high likelihood of overheating, I decided to take the vehicle in for inspection.

Although the owner’s home is only a few kilometers from our shop, the cooling fan continued running throughout the short journey, with the high-temperature warning light briefly illuminating just before arrival.

This was clearly a case of overheating. What could be causing this?

Upon arrival, though the high-temperature warning light had gone out, both cooling fans were still running loudly. As coolant began overflowing from the sub-tank, I stopped the engine.

Opening the service hatch in the rear gate didn’t reveal severe overheating.

However, I noticed all water hoses collapsing due to negative pressure as the temperature dropped, indicating improper pressure regulation in the cooling system.

Forcibly removing the pressure relief valve (radiator cap) revealed that the rubber seat of the pressure valve had expanded, with its center detached.

For comparison, the rubber on a new radiator cap’s pressure valve is this size.

The pressure is regulated in the gap between the metal case and the pressure valve (indicated by the red line). The expanded rubber had blocked the path (radiator → vacuum valve → sub-tank).

The rubber seat’s expansion prevented coolant replenishment from the sub-tank and pressure regulation, allowing coolant in the main circuit to only flow out. This cycle led to coolant depletion.

In rear-engine Sambars of this generation, if coolant becomes low and air pockets form on the engine side, the layout is dangerously prone to sudden overheating as air can’t naturally escape without forced evacuation through the air bleed plug in the engine compartment.

But why did the rubber expand like this?

Although this photo of the radiator cap is post-cleaning, it had engine oil on it when removed. The rubber in the coolant circuit isn’t oil-resistant, causing significant swelling when exposed to engine oil.

Engine oil in the coolant circuit typically suggests major issues like head gasket failure due to cylinder head warping, requiring extensive repairs.

However, we were informed of an engine oil leak dripping from the lower timing belt cover when the vehicle was brought in.

While this oil leak might seem unrelated to the overheating, simultaneous problems often share a root cause.

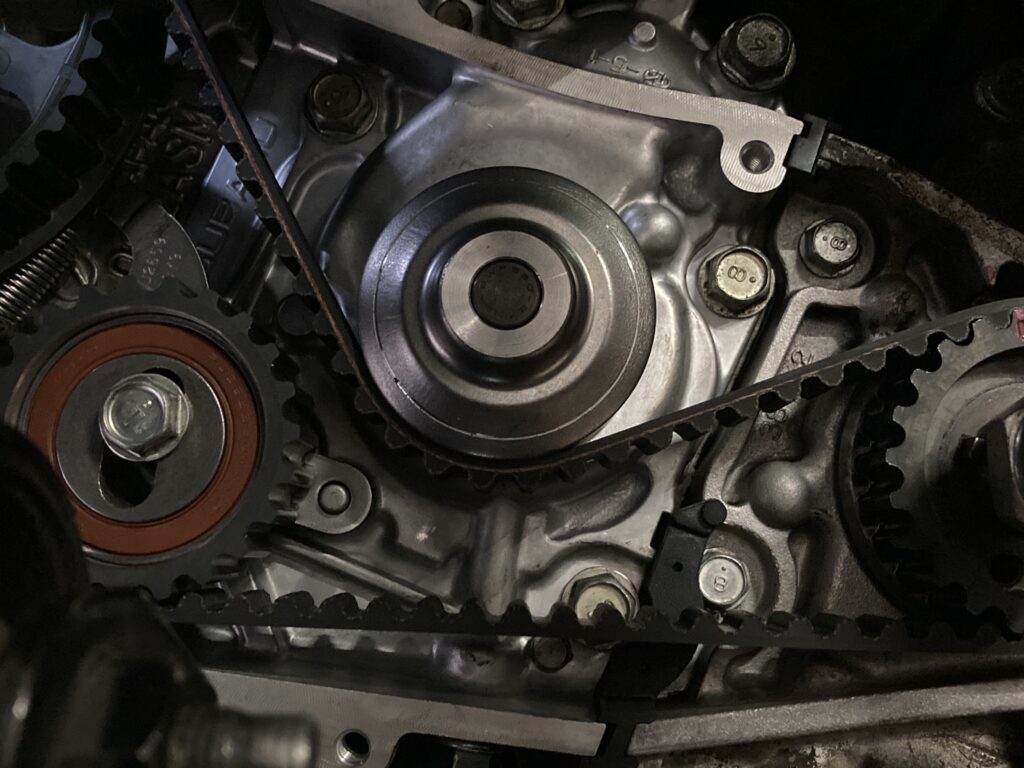

Given the location, I suspected the oil pump and decided to check the condition of the timing belt (changed unusually early at 40,000 km before purchase) and the water pump, likely replaced at the same time.

Disassembly revealed aftermarket parts, as suspected from the timing belt change sticker design.

The aftermarket water pump reportedly had a plastic impeller, so I removed it to replace it with a genuine Subaru part, concerned it might contribute to overheating.

Upon removal, I recalled the unique water pump gasket design for Sambar’s 4-cylinder engine.

This circular area is exposed to high-pressure engine oil.

Observing the oil on the water pump gasket and flange surface, it appeared to be the source of both oil entering the coolant circuit and external leakage.

I might have unnecessarily investigated the oil pump or cylinder head without this observation.

Comparing with the genuine part (right) revealed a metal impeller in the original.

The gasket comparison showed distinctive protrusions on the genuine part to prevent misalignment.

Measuring the gasket groove depth on the water pumps showed the genuine part consistently at 1.8mm, while the aftermarket part ranged from 1.9-2.0mm, suggesting potentially improper compression if using the same cross-section gasket.

I’ll withhold the aftermarket manufacturer’s name, but it’s concerning they couldn’t accurately replicate crucial dimensions.

Using non-OEM approved parts in critical areas is inadvisable. Even for OEM-approved manufacturers, I prefer using parts in packages bearing the auto manufacturer’s logo to ensure quality control.

Engine oil contamination in the coolant circuit typically results in a total loss, especially for rear-engine vehicles like the Sambar with long, complex coolant paths, requiring extensive and costly replacements.

Fortunately, in this case, the contamination seemed minimal. I plan to extend the vehicle’s life through regular, thorough coolant system flushing and inspection/replacement of components degraded by engine oil exposure, such as the radiator cap.

Leave a Reply