“It’s time for an oil change, so I’d like to request that service, but I also have another issue I’d like to consult with you about. Recently, I’ve noticed a slight gasoline-like smell inside the car. I suspect the common issue of a fuel pump failure.”

This was the message from our customer.

2011 model Alfa GT 2.0JTS selespeed, mileage: 66,000km

It’s troubling that fuel leaks are considered “common,” but the fuel pumps in Alfa Romeos from this era frequently experience leakage problems.

Gasoline is a highly flammable liquid (flash point of -40°C) and extremely dangerous, but there seems to be no sign of a recall being announced.

Even with age, fuel leakage problems are extremely rare in Japanese cars. However, in foreign cars, the frequency increases significantly, and this tendency seems particularly strong in Alfa Romeo and Fiat pumps from this era.

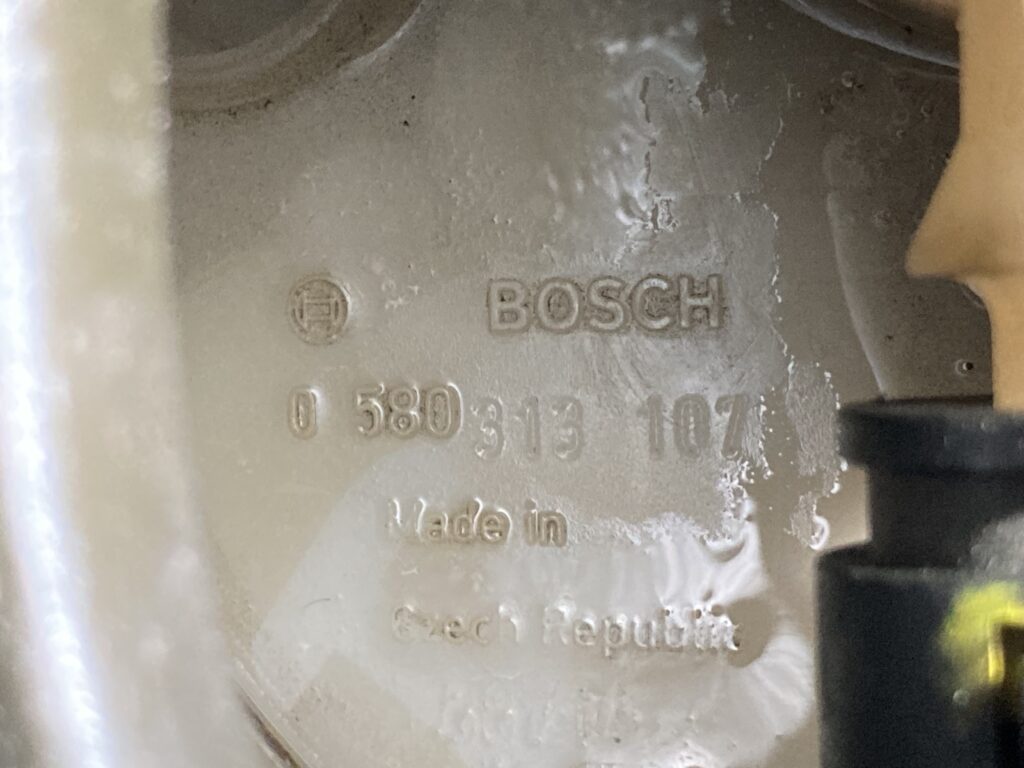

We’re almost certain it’s a gasoline leak from the fuel pump, but to ensure there are no delays when ordering parts, we started by reading the number engraved on the top of the pump. This is because multiple types of parts may be installed in the current vehicle, or because traceability might be insufficient.

The fuel pump service hole is located at the front edge of the luggage compartment, near the bottom of the rear seat backrest.

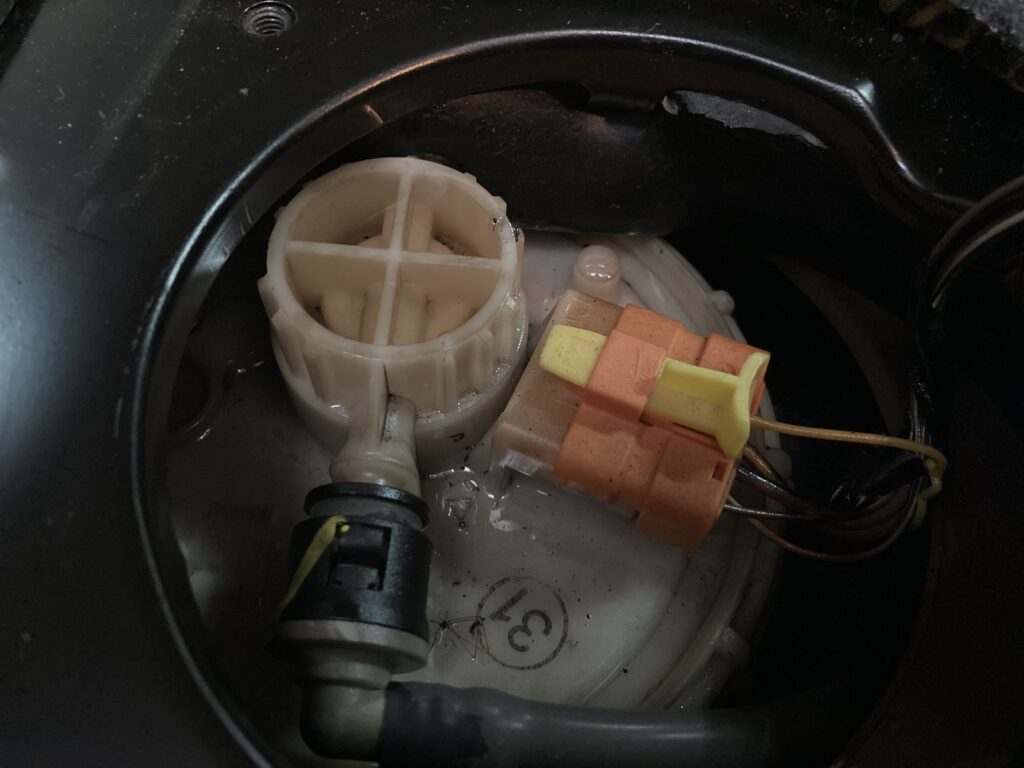

After removing three bolts and opening the cover, we found gasoline pooled to the brim in a protrusion with cross-reinforcement. On the back side of this protrusion is the fuel pressure regulator. This is the part where fuel passes through at high pressure.

After drying the wet surface on top of the pump with air, we could confirm the supplier BOSCH’s part number engraving and that it was manufactured in the Czech Republic.

|

|

Even without a recall notice, we sourced the genuine part hoping that the automobile manufacturer might have implemented some countermeasures for these frequent issues, but we were disappointed when we received a pump that looked no different externally. It seems that they’re not very concerned with anything except things that stimulate consumers’ senses, like flowing curves or engines that produce pleasant sounds.

Let’s regroup and move on to the replacement work.

As you can see from the previous photos, the service hole and the center position of the fuel pump are misaligned, making it impossible to remove the fuel pump through this hole.

This is a puzzling layout that’s common in foreign cars, but perhaps the consideration for service technicians that’s commonly seen in Japanese cars is actually a highly advanced technology.

Since the black plate near the pump also serves to secure the rear seat, we first remove the rear seat backrest.

The backrest mounting bolts probably haven’t been touched since the car was new, but there are forgotten bolts and nuts, or some are angled causing thread damage, and fixing these issues delays the progress of the main task.

Now, the next part is the most difficult step in the entire process: removing the large plastic screw (bezel) that secures the top of the pump.

We applied a custom-made special tool that we had prepared before starting work. Since it’s strongly stuck, we loosened it boldly yet carefully to avoid injury.

It feels really good to overcome a difficult challenge with a self-made tool.

The fuel pump is of the currently mainstream in-tank type, meaning it’s completely submerged inside the fuel tank. When I first saw this method nearly 40 years ago, I was worried about whether sparks from the electric pump motor might cause ignition.

Ideally, this plastic bezel should be replaced with a new one. Imported car parts often include many plastic products that have inferior dimensional stability compared to domestic parts, making them potentially unsuitable for reuse.

Assembling the bezel was also difficult until I got used to it. There might be slight dimensional changes in the plastic fuel tank as well. It often works well to use the special tool to push it in slightly and then engage the first thread partially with a “click” in parallel.

Today was a busy day, with preparation for the continued inspection of an Imola Limited Mito and diagnosis of a Carry with a malfunctioning freezer in parallel, but we were able to successfully complete all the work.

![[商品価格に関しましては、リンクが作成された時点と現時点で情報が変更されている場合がございます。] [商品価格に関しましては、リンクが作成された時点と現時点で情報が変更されている場合がございます。]](https://hbb.afl.rakuten.co.jp/hgb/0f2d1037.3be248e3.0f2d1038.da8a7e18/?me_id=1232319&item_id=10071801&pc=https%3A%2F%2Fthumbnail.image.rakuten.co.jp%2F%400_mall%2Femuzuparts%2Fcabinet%2F00746040%2Fimgrc0097589627.jpg%3F_ex%3D240x240&s=240x240&t=picttext)

Leave a Reply