We received this Nissan Clipper van with the complaint that the air conditioning doesn’t work at all, and when the A/C switch was turned on, it only blew air without cooling.

The automotive air conditioning cooling cycle (vapor compression type) achieves continuous cooling through the following circulation of refrigerant within a closed circuit:

Compression: The compressor compresses gaseous refrigerant to high temperature and high pressure

Condensation: In the condenser (outdoor unit + cooling fan in the engine compartment), the high-temperature gas releases heat and changes to liquid

Expansion: The expansion valve rapidly depressurizes the high-pressure liquid, turning it into low-temperature, low-pressure liquid (mist) and introducing it to the evaporator

Evaporation: Inside the evaporator (indoor unit installed inside the air conditioning duct), the liquid refrigerant evaporates, absorbing heat from surroundings for cooling → the vaporized refrigerant returns to the compressor. Cool air is created by blowing air over the cooled evaporator exterior.

There’s sometimes a misunderstanding, but a gauge manifold (equipment that measures high and low pressure in the refrigerant circuit) is a pressure gauge, so this instrument alone cannot determine the refrigerant charge amount. While it can detect if refrigerant has completely (or mostly) leaked out, when the A/C is stopped, liquid and gas coexist inside the refrigerant circuit and pressure equalizes.

|

|

The cooling cycle might be easier to understand if you think of the expansion valve in the refrigerant circuit as something like a spray nozzle, and imagine a spray can where liquid is continuously replenished.

A spray can with the appropriate amount of liquid and internal pressure can spray stably, and that continuous spraying makes the spray can ice cold, right?

It’s easy to imagine that excessive refrigerant filling in a circuit with limited internal volume is inappropriate. And you can probably understand that even if the refrigerant is somewhat low, it doesn’t greatly affect cooling capacity. Therefore, when an air conditioner doesn’t work due to refrigerant shortage from leaks, it’s safe to assume that the refrigerant is considerably low.

Now, back to the Clipper diagnosis.

2011 model year GBD-U71V 3G83 4AT mileage 146,000km

Since the air conditioning wasn’t working at all, we first checked the refrigerant. When trying to connect the gauge manifold, we noticed something unusual. Due to abnormally high pressure on the high side, the chuck was tight and couldn’t be attached.

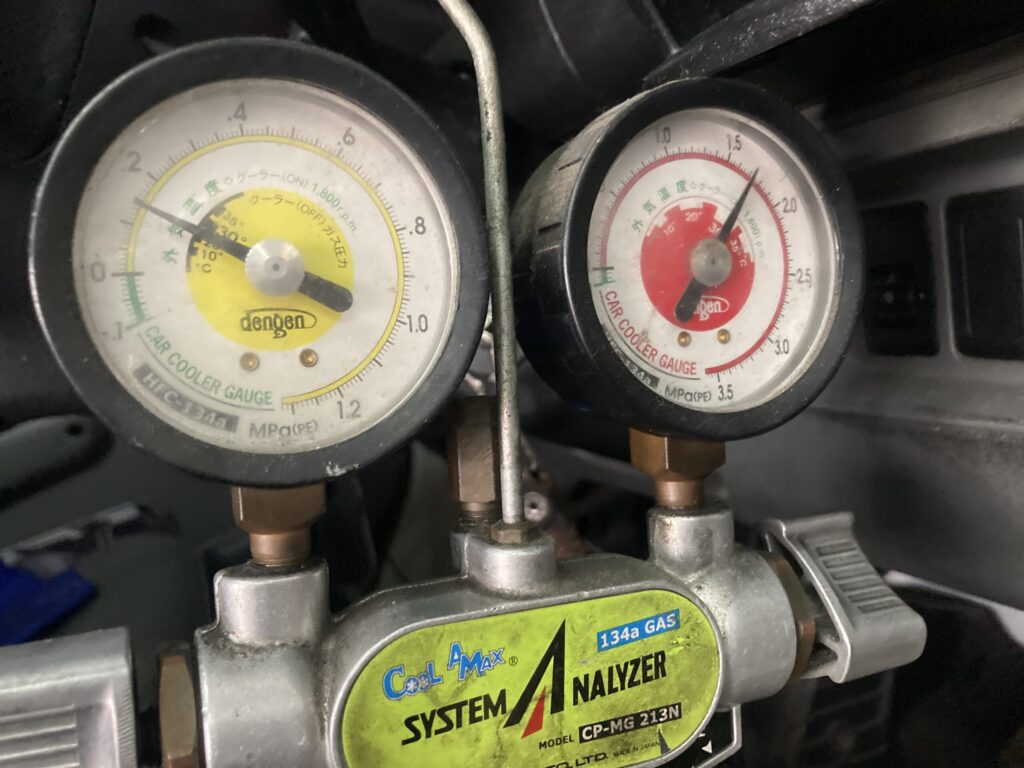

On the other hand, the low side could be attached and showed 0.8MPa, which is high, but the high side seemed to easily exceed the pressure switch operating pressure (probably over 2.0MPa). We temporarily removed refrigerant gradually from the low side and attached the chuck to the high side.

When we tried the air conditioning again, the compressor turned ON normally, probably because it was below the pressure limit, and the condenser cooling fan also operated. However, we could hear some groaning from the compressor, the high pressure was high at 1.7MPa, and the low pressure seemed too low. The ambient temperature at this time was 25°C.

Such abnormal pressure readings suggest there’s a location where refrigerant flow is restricted. That location acts like an expansion valve, so temperature differences occur in the piping before and after the abnormal location. This time, no such temperature difference was observed upstream of the expansion valve, so we considered it highly likely that the expansion valve itself was malfunctioning (somewhat clogged) and proceeded with replacement.

The expansion valve is located deep in the A/C piping under the passenger seat.

The removed expansion valve showed no visible defects on the exterior.

This Clipper’s air conditioning system has excellent serviceability, with a structure that allows easy evaporator removal. This is because evaporator replacement in typical light vehicles is relatively difficult work, as shown in the next article.

Due to the structure without an air conditioning filter, accumulated dust was adhered to the evaporator surface as shown.

Just cleaning this considerably improves cooling capacity.

And after reassembling everything back to original condition,

The gauge pressure achieved an ideal balance.

Leave a Reply