The refrigerated light truck now in its 8th year is about to reach 250,000 kilometers in mileage.

It drives approximately 30,000 kilometers annually, mainly in urban areas with extremely frequent stop-and-go traffic. The fact that it has operated almost trouble-free up to this point is undoubtedly due to the driver’s careful attention to the vehicle.

This time, I inspected the vehicle because coolant-like fluid was dripping underneath. This is a very good habit. Pre-operation inspections are important.

2017 model DA16T R06A 3AT, mileage 249,000km

This vehicle had been maintained with minimal preventive maintenance. When I inspected the water pump, which hadn’t been replaced despite the high mileage, I found it was indeed leaking.

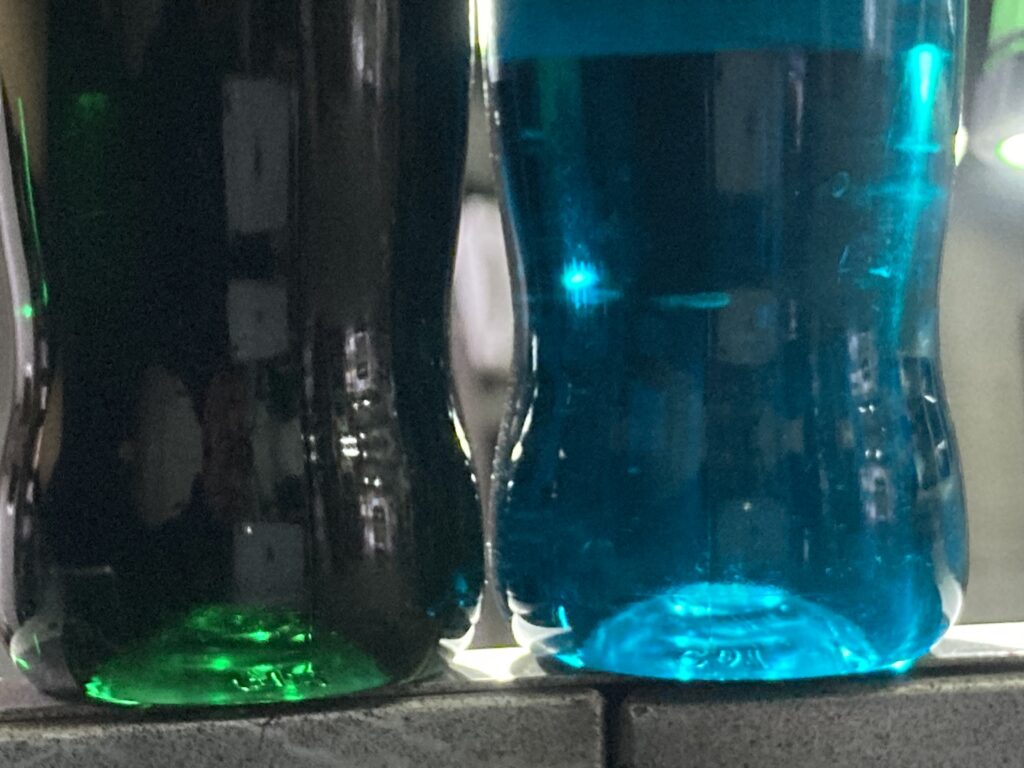

However, the coolant appears green. This vehicle should have blue Super Coolant. It seems someone mistakenly mixed different types of coolant.

The bottle on the left contains coolant drained from the vehicle, while the one on the right contains new coolant. There have been cases where mixing conventional long-life coolant with Super Coolant causes gelation that clogs waterways. The coolant drained this time also seemed to have slightly higher viscosity.

Now, it appears the coolant leak isn’t just from the water pump, as leak traces were also found near the oil pan.

Following the trail, it seems to be coming from a thinner coolant hose connected to the throttle body.

While we can still somehow access this side, the opposite end of the hose passes under the intake manifold toward the cylinder head.

Normally, the DA16T Carry has a cover (floor service lid) on part of the cargo bed that can be detached for maintenance, but with the large refrigeration box mounted and fixed with refrigeration pipes occupying the cargo bed, it can’t be easily opened.

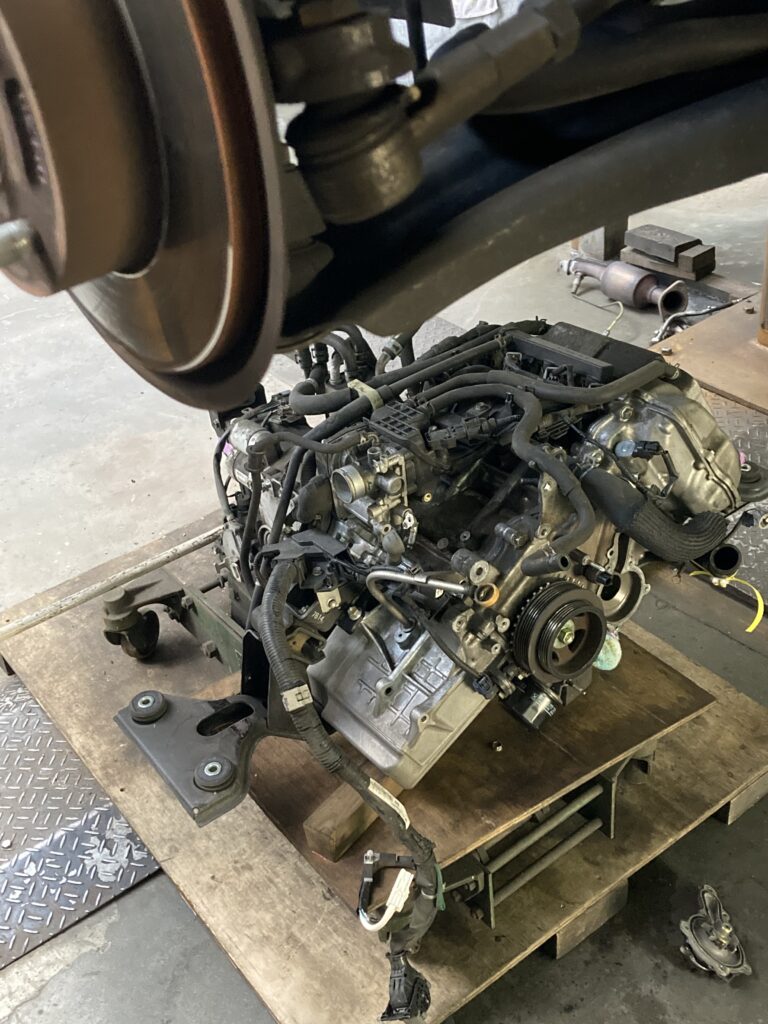

The simplest method in such cases is to boldly detach the engine.

Automobile manufacturers employ various techniques like structural integration (componentization) to assemble complete vehicles in a short time. In contrast to foreign cars that seem to place extreme emphasis on assembly direction benefits (reducing work hours), Japanese cars seem to be designed with consideration for making disassembly (removal) work equally easy.

In this case, thanks to Suzuki’s thoughtful consideration (as I perceive it), after disconnecting several connectors and the body ground, coolant pipes, fuel lines, air intake duct, exhaust pipe, and propeller shaft, the engine could be detached from the vehicle in surprisingly little time.

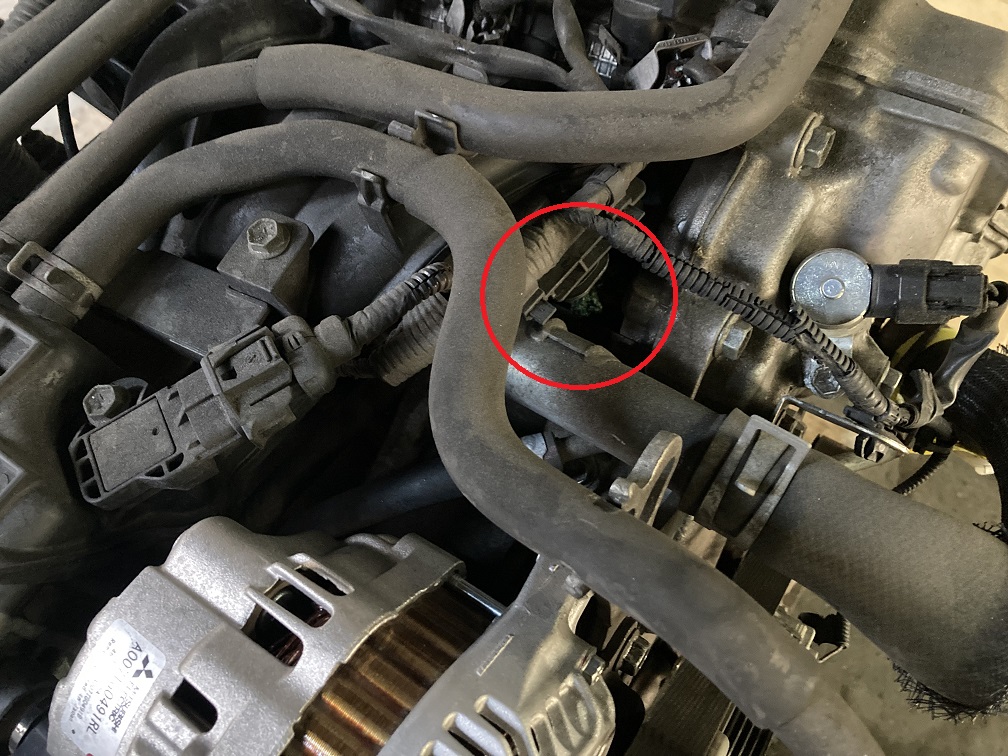

Now, the target hose connection is in this red circle.

What I find strange is that of the two hoses connected to the throttle body, one is leaking while the other doesn’t even show signs of seepage.

When comparing them, there was a difference in appearance (hose surface). One has a smooth surface, while the leaking one has an uneven texture. This was also true for the new replacement parts. This will be a key inspection point for the same engine type in the future.

Leave a Reply